Automated System of the Central Control Center for Cascade Hydropower Stations in the Watershed

- Overview

- Main Features

- Main Indicators

- Main functions

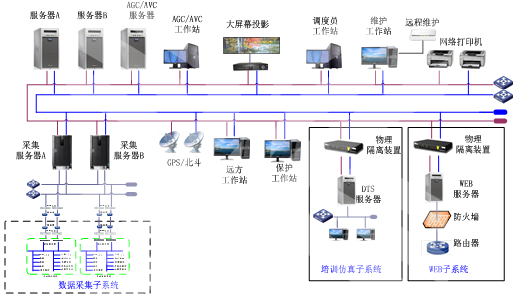

- Device Configuration

The XSJ-1000J basin-level cascade hydropower station centralized control center automation system is designed based on the principles of software platformization and functional customization. It employs component technology, object-oriented technology, database technology, and cross-platform technology, featuring a unified support platform that complies with IEC 61970 standards. This platform supports the construction of various application subsystems for the dispatch center and centralized control center, meeting the automation, informatization, and standardization requirements of the centralized control center and dispatch management. The construction and application of the centralized control center automation system are beneficial for reducing personnel and increasing efficiency at the hydropower stations under its jurisdiction, improving the management level of centralized monitoring of hydropower stations, and is an important component for achieving unattended or unmanned management of hydropower stations.

Applicable to centralized control applications for two or more hydropower stations.

Complies with IEC 61970 standards and various communication interfaces and protocols, featuring high openness and scalability.

Comprehensive cross-platform support, capable of running independently on mainstream operating systems such as Windows, Unix, Solaris, HP-UX, and Linux, and also supports mixed operation across different operating systems, making system configuration and costs more reasonable.

Provides an integrated tool for graphical modeling, making drawing and modeling efficient and convenient, with features for automatic area drawing and intelligent graphic generation.

Data display methods are vivid and diverse, featuring rich visualization graphics and animation technology, capable of vividly presenting steady-state, dynamic, and transient data.

Database selection is available, supporting mainstream relational databases such as SQL Server, Oracle, and MySQL, allowing users to choose freely based on their usage habits and needs.

Easy to use and maintain, utilizing the maintenance diagnostic tools provided by the system, maintenance personnel can quickly and accurately determine the location and cause of anomalies and failures.

Data Collection and Processing

Automatically collect all information required for monitoring and controlling various hydropower stations, including real-time operational data, real-time calculation data, historical data, and recorded data such as analog quantities, status quantities, digital quantities, electrical energy, SOE, etc. Perform validity and correctness checks and processing on the collected data.

Safety Operation Monitoring

The central control center operator can monitor the monitoring objects of each hydropower station through the human-machine interface device of the central control center computer.

Trend Analysis

The trend analysis function is used to display the changes of some variables. The trend analysis program can display trend data in curve form on the trend display screen. Trend data includes temperature-time trend monitoring of generator and turbine bearings during startup, temperature change rate, and display of temperature difference values between various bearing pads.Accidents and Alarms

The central control center can receive limit alarm signals and protection accident signals from various hydropower stations, respond to analog quantity limits, gradient limits, switch quantity status changes, and various information such as self-diagnosis faults and protection accidents sent by the power station after confirmation; in the event of an accident, automatically launch the corresponding accident screen and accident handling guidance, with flashing and color-changing screens, display misalignment signals, and print accident memory records.

Accident Memory and Replay

Perform accident memory processing on real-time data. The operating modes and main parameters of the power station before and after the accident should be recorded and preserved.

Human-Machine Interface

Real-time database and historical database management functions, providing graphical interface database generation and maintenance tools; configuration interface, rich static and dynamic graphic elements, SVG graphic format support.

Control and Regulation

Supports four control and regulation modes: station local layer, plant layer, central control center layer, and grid dispatch layer control and regulation. The main content includes switching and disconnecting, unit start-stop, active and reactive power regulation, gate control, transformer tap adjustment, pressure plate engagement and disengagement, setting of fixed values, etc.

Automatic Generation Control (AGC)

Automatically allocate to each unit of various hydropower stations based on total active power and frequency set values. Depending on the operating mode of the power station, it has functions such as active joint control, specified frequency control, and optimized operation.

Automatic Voltage Control (AVC)

Automatically allocate to each unit of various hydropower stations based on total reactive power and voltage set values.

Statistics and Reports

The system supports real-time data and historical data, can easily generate and modify tables, and can conveniently query and maintain the database, allowing for the free generation of reports for any past period, such as daily reports, monthly reports, quarterly reports, annual reports, etc.

Operational Management Guidance

The system accumulates and calculates the operating parameters of the main electromechanical equipment of each hydropower station, accumulates operational data, provides operational management guidance for the central control center duty personnel, and provides a basis for safety analysis.

System Communication

The system can monitor communication channels and communication status, displaying communication fault alarm information and communication status information on the operator workstation, and should be able to switch redundant communication channels automatically or manually.

Configure a set of high-precision clock synchronization devices to achieve clock synchronization of the entire system. The clock synchronization system can receive GPS and Beidou timing signals separately, connect to the computer monitoring control network through Ethernet interface, and perform NTP clock synchronization for all computers within the network.System Self-Diagnosis and Self-Recovery

The system has complete hardware and software self-diagnosis capabilities, including online diagnosis, offline diagnosis, and request diagnosis. During online operation, it should perform self-diagnosis on the hardware and software within the system and indicate the faulty module.

News

Information release supports WEB publishing and mobile terminal APP publishing, with the information release function provided by WEB and mobile terminal APP servers, located in non-real-time control areas. Information release has complete security measures, including user login authentication mechanisms and information encryption transmission mechanisms.

Previous:

The next one: