Online Monitoring System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

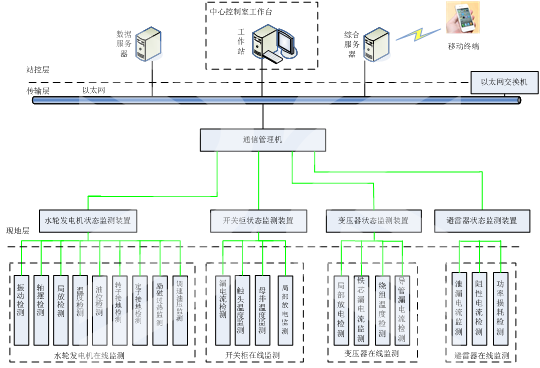

The XSJ-1000 hydropower station online monitoring system is developed by our company in response to the requirements for minimal staffing or unmanned operation, centralized monitoring, and remote operation management in many domestic hydropower stations. It gradually adapts to the technological development trend towards intelligent hydropower stations, follows the latest relevant standards in the fields of water conservancy, hydropower, and automation, and is designed for typical faults in the main equipment of small and medium-sized hydropower stations, resulting in a highly practical and cost-effective online monitoring and fault diagnosis system.

The system mainly includes stability monitoring of hydropower units, insulation monitoring, temperature detection, stator grounding, and rotor grounding monitoring; overheating monitoring of the generator auxiliary equipment excitation regulator's thyristor, oil pressure and working power monitoring of the governor; insulation monitoring and temperature detection of transformers, temperature monitoring and insulation monitoring of circuit breakers and switchgear busbars, cable heads, online monitoring of lightning arrester discharge current, and abnormal alarms for equipment status parameters, as well as early warnings for the development trends of equipment status parameters. Based on this, fault diagnosis and defect analysis of electrical equipment are conducted through the upper computer monitoring system, along with maintenance management, spare parts management, and mobile management via an APP. The application of this system in hydropower stations allows for real-time understanding of the health status and lifecycle of equipment, which is beneficial for the operational safety of electrical equipment in hydropower stations, reduces planned maintenance, and improves operational efficiency. It is an important component for achieving unmanned or minimal staffing in hydropower stations, facilitating the intelligent, informational, and modern management of hydropower stations.

Applicable to new construction and renovation projects of small and medium-sized hydropower stations, as well as centralized monitoring and management of online monitoring for hydropower station clusters in regions and river basins.

High integration level

Abandon the configuration mode of a set of online monitoring equipment for each parameter for large units. Based on the high cost-performance requirements of online monitoring for small and medium-sized units, use self-developed multi-parameter online monitoring equipment with modular design aimed at the tested equipment. The equipment configuration is simplified and applicable, overall costs are controlled, and it can achieve the purpose of on-site joint diagnosis of various fault characteristics.

Comprehensive monitoring

For the typical fault characteristics of the main electrical equipment in small and medium-sized hydropower stations, the online monitoring of power equipment in the station is divided into three major parts: online monitoring of hydropower units, online monitoring of booster transformers, and online monitoring of high-voltage switchgear. The design of software and hardware systems fully considers the selection, embedded installation, and development of monitoring sensors for different power equipment in the station. Different online monitoring and fault diagnosis solutions are adopted for the typical fault characteristics of different equipment, covering all important links such as power generation and transmission in hydropower stations.

Reliability

The electromagnetic environment of the power system in small and medium-sized hydropower stations is exceptionally complex, characterized by strong electricity and strong electromagnetic interference. Therefore, the reliability of the signal is the basis for determining whether the online monitoring and fault diagnosis functions of the equipment can be truly realized. The design must ensure the reliability of the system from various aspects, including sensor selection, communication methods, installation locations of measurement points, system anti-interference, and grounding.

Advancement

Use cost-effective wireless sensing technology, artificial intelligence fault diagnosis algorithms, and expert reasoning systems, as well as an online monitoring network based on Internet of Things technology, and a network information integration solution based on Web Service.

Openness

The system should fully consider the rapid development of current technology, future equipment upgrades, and the information exchange and sharing with other systems, paying special attention to the system's openness and the application of international and national standards.

Safety

The system should comprehensively consider equipment safety, network security, and data security. The installation of on-site sensors must ensure that it does not affect the operational safety of electrical equipment. Communication security must be guaranteed between the on-site layer and the station control center, and reliable measures must be taken to prevent illegal access, intrusion, and attacks on the monitoring center's equipment. Data should be stored in a combination of station control layer storage and remote service center cloud storage, with strict user permission control for data access, and effective rapid emergency response and log recording for anomalies.

Ease of management and maintenance

The system uses fully Chinese, graphical software to manage and maintain the entire online monitoring system. The human-computer dialogue interface is simple, clear, friendly, easy to operate, and flexible, facilitating the configuration of the online monitoring system. It adopts stable and easy-to-use software and hardware, completely eliminating the need for any specialized maintenance tools, significantly reducing operation and maintenance costs.

Real-time monitoring

Mainly includes stability monitoring of water and electricity units such as vibration and sway, insulation monitoring of partial discharge and leakage current, temperature detection, stator grounding, rotor grounding monitoring; overheating monitoring of the excitation regulator of generator auxiliary equipment, oil pressure and working power monitoring of the governor; insulation monitoring and temperature detection of transformers, temperature monitoring and insulation monitoring of circuit breakers and switch cabinet busbars, cable heads, and online monitoring of lightning arrester discharge current. The system provides screen configuration and system configuration tools, allowing customization of user monitoring screens, real-time curves, data alarms, and other functions according to user needs.

Fault diagnosis

Based on advanced fault diagnosis algorithms and expert systems, comprehensive analysis of online monitoring data is conducted to achieve abnormal state alarms and trend warning functions.

Mobile management

The system supports information publishing, human-computer interaction, and process operations through mobile terminals, enabling mobile office for online monitoring and production management systems of hydropower stations.

Previous:

The next one: