Remote Intelligent Operation and Maintenance System for Hydropower Stations Based on Cloud Platform

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

The XSJ-1300X cloud-based remote intelligent operation and maintenance system for hydropower stations is an integrated system developed using advanced intelligent sensors, mobile internet, big data, cloud services, and new technologies such as automation and intelligence in hydropower stations. The system is designed for flexible configuration based on software platformization and functional modularization, allowing users to choose equipment and functional configurations according to their technical requirements and investment conditions for operation and maintenance management of hydropower stations.

The widespread application of the cloud-based remote intelligent operation and maintenance system for hydropower stations is beneficial for the safe operation of hydropower stations, improving efficiency, information sharing, reducing personnel while increasing efficiency, and integrated comprehensive management. It achieves a high level of automated control and intelligent management, making it an important system device for achieving unattended operation or monitoring of hydropower stations. It can reduce enterprise operation and maintenance costs, optimize economic operations, enhance the economic benefits of power generation in hydropower stations, and improve the intelligent, informational, and modern management levels of hydropower stations.

The cloud-based remote intelligent operation and maintenance system for hydropower stations has been widely applied and highly recognized by users in the domestic and international hydropower industry market.

Scope of Application

It is suitable for remote intelligent operation and maintenance management of small and medium-sized hydropower station groups with about 50 hydropower stations or a total installed capacity of less than 250MW in the region. It can also be expanded based on user needs.

1. Intelligent Operation

Hydropower stations have advanced application functions such as fully automatic startup and shutdown, automatic shutdown in case of accidents, automatic power generation, economical operation, and automatic power generation based on water levels. The reliability of coordinated control of hydropower units is high, and the operational adjustment is fast and sensitive. The automatic control operation of the units can be managed independently or connected to the intelligent operation and maintenance center for management, achieving joint scheduling control and optimized economic operation management of cascade hydropower stations.

2. Management Informationization

The intelligent operation and maintenance center system has big data cloud services for unified management of hydropower station groups and flood control of reservoir basins, including functions such as panoramic display of data, images, and videos, safety monitoring, intelligent alarms, operation and maintenance management, protection information management, statistical analysis, and equipment management, providing users with big data display, analysis, and decision-making. It can also interconnect with the dispatch center and mobile terminals to achieve comprehensive information management of intelligent operation and maintenance for hydropower station groups.

3. Equipment Integration

The system adopts a highly integrated and standardized integrated control platform, sharing platform hardware resources, simplifying the configuration of workstations, servers, and communication devices, fully supporting the data integration design and application display of hydropower station data, images, videos, and security linkage, achieving integrated operation, maintenance, and usage. It can use wireless public communication networks and highly reliable cloud servers, significantly saving investment and operation and maintenance costs for users.

4. Mobile Services

Through the mobile terminal APP, remote management of various hydropower stations' operational control, map positioning, data monitoring, video surveillance, intelligent inspection, equipment fault diagnosis and early warning, and operation reports is achieved, enabling mobile office management of hydropower station groups.

5. System Openness

The system provides standardized and customizable external data interfaces, facilitating the access of data from other intelligent devices in hydropower stations or other systems, achieving data sharing, resource utilization, and simplified operation and maintenance management. The configuration of equipment is made easier, significantly reducing users' investment in later modifications, upgrades, or construction of hydropower stations.

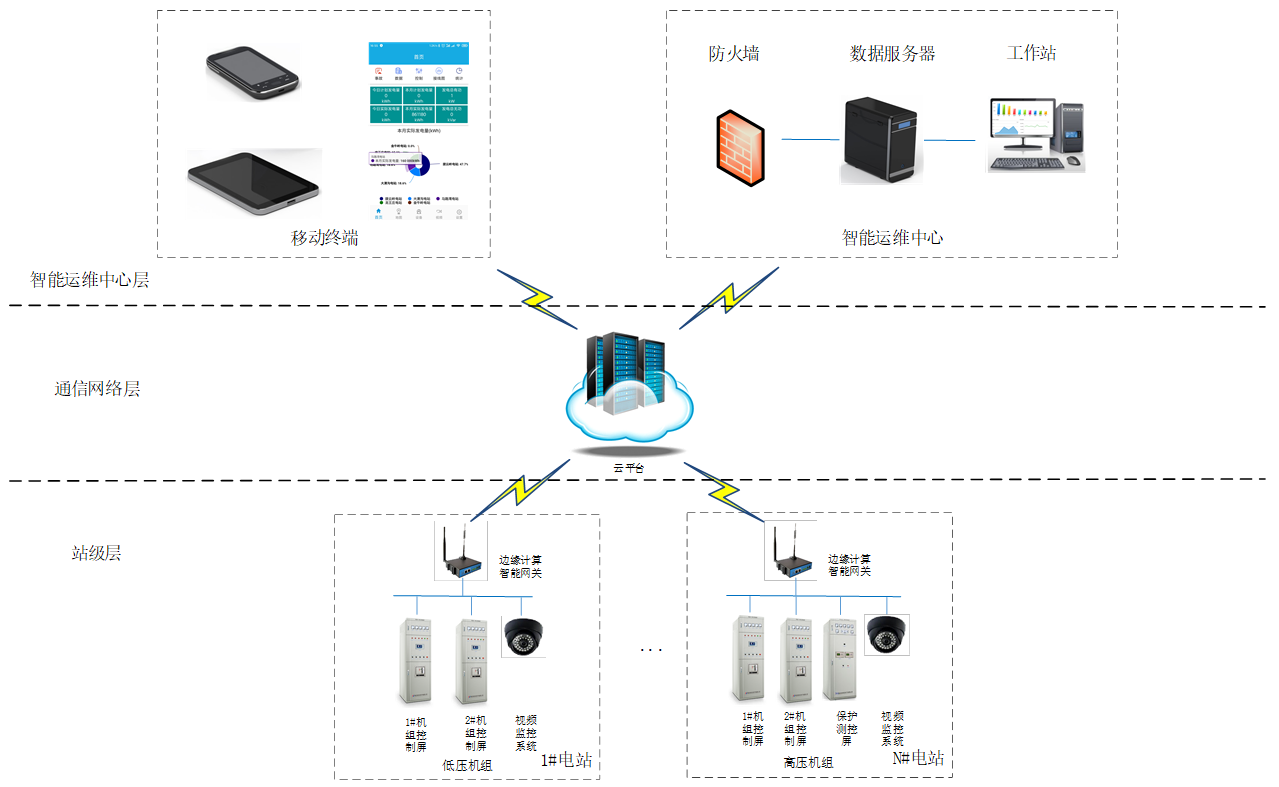

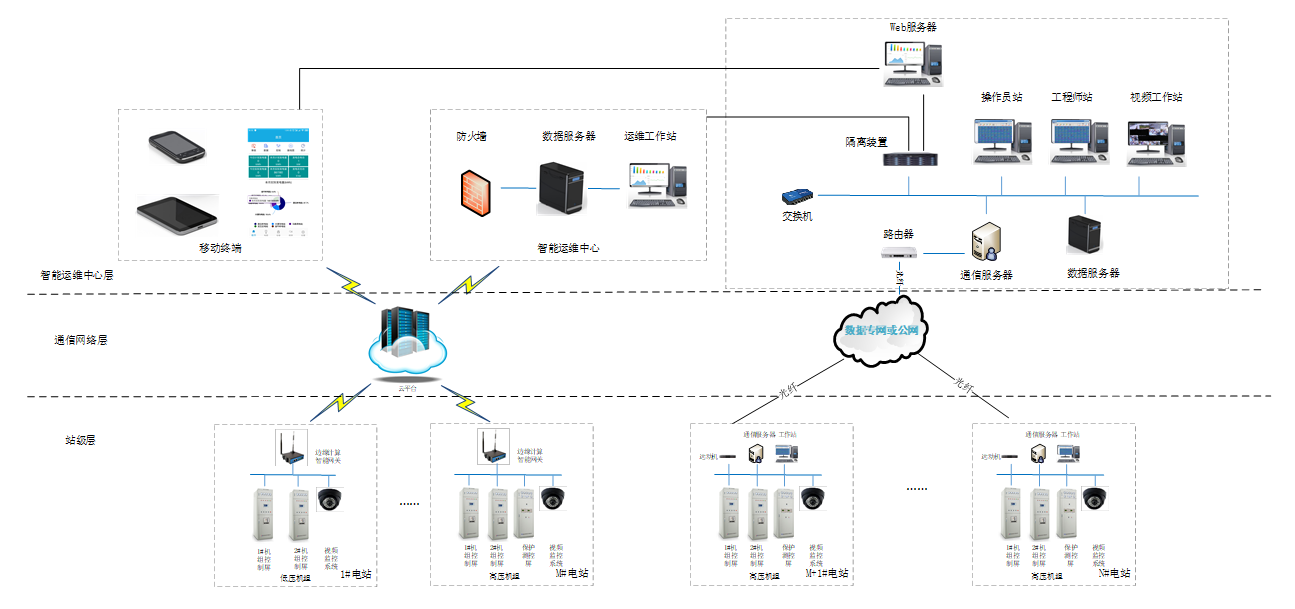

System Architecture

The system is designed based on a layered distributed system architecture, mainly including the intelligent operation and maintenance center, communication network, and hydropower station level.

The intelligent operation and maintenance center mainly includes a cloud platform data center, client computer supervision system, and mobile operation and maintenance system (including intelligent inspection management, etc.).

The communication network can be entirely wireless, mainly including the communication network between the intelligent operation and maintenance center and each hydropower station, and the communication network between the intelligent operation and maintenance center and each mobile terminal.

The communication network mainly adopts wireless public networks such as 4G, 3G, 2G, and IoT communication, with devices mainly including edge computing intelligent gateways, IoT gateways, routers, and other network and security devices.

The communication network can also adopt a wired + wireless method, using wired communication for hydropower stations with high real-time and high stability communication requirements between the hydropower station and the intelligent operation and maintenance center, while other hydropower stations use wireless communication.

The hydropower station level mainly includes application systems such as computer monitoring, video surveillance, and security fire monitoring, as well as network devices such as edge computing gateways that communicate with the intelligent operation and maintenance center.

1) System architecture based on fully wireless communication.

Hydropower stations upload data to the cloud platform data server through edge computing intelligent gateways, where the data server processes, stores, counts, and analyzes big data for the station, and transmits relevant data from the hydropower station through mobile intelligent terminal applications such as IPAD or Mobile APP or computer client workstation applications.

The fully wireless communication method is suitable for small hydropower stations located in relatively remote areas, which do not have wired access capabilities and do not have high real-time communication requirements for the control of the station units.

2) System architecture based on wireless + wired communication.

Some hydropower stations connect to the intelligent operation and maintenance center using fully wireless communication, while others connect through wired communication (data private network or operator public network) and transmit relevant data from the hydropower station through mobile intelligent terminal applications such as IPAD or Mobile APP or computer client workstation applications.

Wired communication is usually applied to medium and large high-pressure hydropower stations that have wired access capabilities and have high real-time communication requirements for the control of hydropower station units.

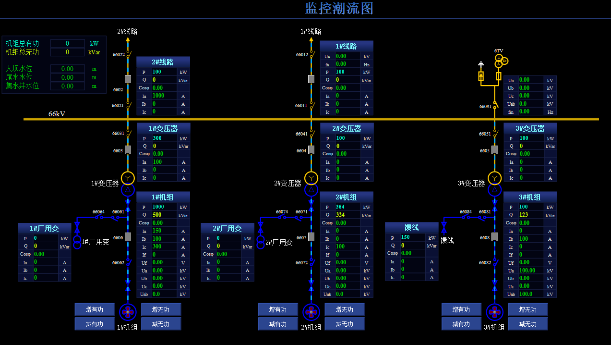

1. Remote Operation Control

Mainly includes remote operation control of unit start and stop, valve switching, auxiliary machine start and stop, circuit breaker operation, knife switch operation, etc., as well as power regulation control for unit speed adjustment and excitation.

2. Panoramic Display

Mainly includes displaying online power, power generation, total active power, average plant power consumption rate, average water consumption rate, protection alarms, etc.; displaying the location of each power station on the map, as well as the operational status of each power station, daily power generation, upstream and downstream flow, water level, etc.

3. Safety Monitoring

Mainly includes video monitoring, security monitoring, access control systems, etc., for real-time safety monitoring and recording of facilities such as the plant area, dam, gate, and reservoir.

4. Operation and Maintenance Management

Mainly includes operation logs of hydropower stations, defect management, operation tickets, work tickets, and inspection management, etc.

5. Protection Information Management

Mainly includes microcomputer protection, fault recording, and automatic control of various hydropower stations, as well as recording, displaying, and fault analysis management of operational faults and accident information.

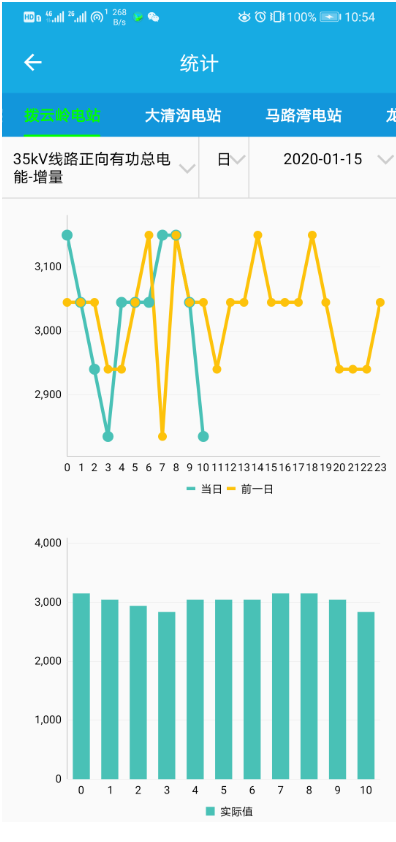

6. Statistical Analysis

Mainly includes maximum, minimum, and average values of electrical quantities such as voltage and current, as well as non-electrical quantities such as water level and pressure, online power, unit power generation, comprehensive plant power consumption, comprehensive plant power consumption rate, water utilization rate, power generation plan completion rate, relative value of power generation revenue, power generation utilization hours, power generation water consumption rate, average accuracy rate of flood forecasting, number of unplanned unit outages, automatic startup success rate, and correct action rate of relay protection and safety automatic devices.

7. Intelligent Alarm

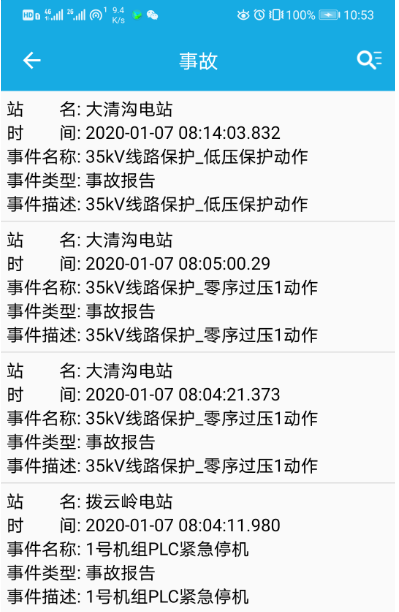

Mainly includes system protection actions, equipment self-check anomalies, switch position changes, limit exceedances, and other fault alarm information, with abnormal operation and accident reports of the power station automatically pushed to the intelligent operation and maintenance center and mobile terminal operation and maintenance duty and management personnel, using various methods to remind users to handle faults in a timely manner.

8. Equipment Management

Mainly includes equipment rating, equipment anomalies, equipment maintenance, equipment ledger records, inquiries, and usage management.

9. Document Management

Mainly includes file retrieval, file borrowing, data archiving, file management, log management, and other information.

10. Event and Report Management

Mainly includes classified display of events occurring in each subsystem, supporting event classification queries and export operations; statistical management of operational reports, accident and fault reports, and equipment operation reports.

11. WEB Information Release

Mainly includes access to various screens, data, and alarm items of the power station, browsing real-time alarm information, historical alarm information, screens, reports, etc., with various screens, information, and reports being printable.

12. System Management

Mainly includes user management, plant management, and operation log management.

Mobile Intelligent Terminal Functions

1. Operation and maintenance management personnel of hydropower stations can access the intelligent operation and maintenance center system through mobile intelligent terminals anytime and anywhere, browsing and querying the safety operation status of equipment and facilities systems at various hydropower stations on-site, and implementing remote operation and management guidance.

2. Mobile intelligent terminal functions include power station operation and control, map display, panoramic data, video monitoring and statistical data display, accident reporting, intelligent inspection, and other functions.

3. Through mobile terminals, remote operation control of power station unit start and stop, circuit breaker operation, valve switching, and other equipment can be performed, monitoring the operation data, switch status information, real-time video images of the power station, and remotely modifying the operational parameters of the hydropower station system. Using map navigation and inspection task planning requirements, intelligent inspection management of each power station can be implemented through mobile terminals, recording inspection time, inspection content, and other information.

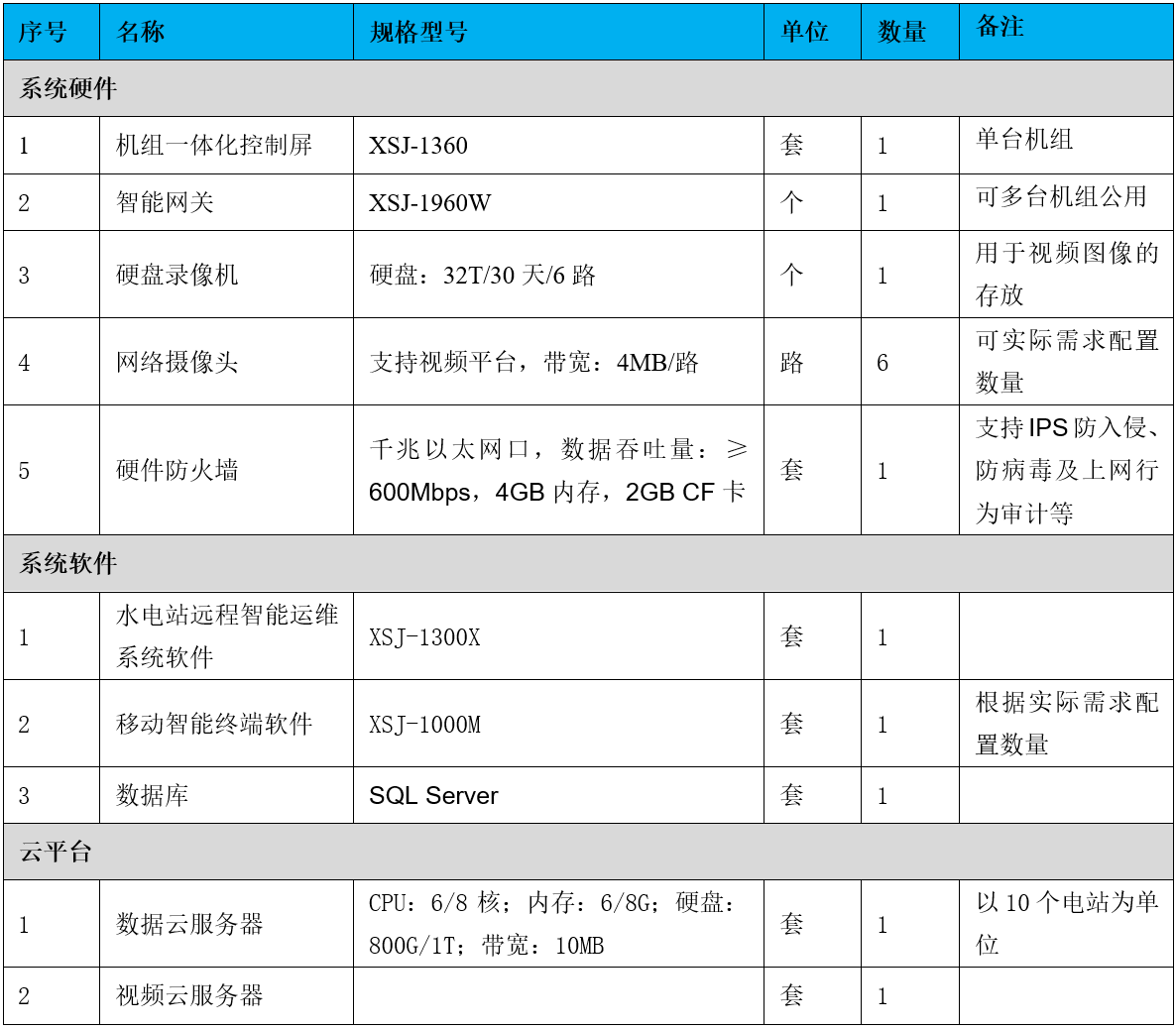

Cost-effective equipment configuration table for a hydropower station connected to a remote intelligent operation and maintenance system

Previous:

The next one: