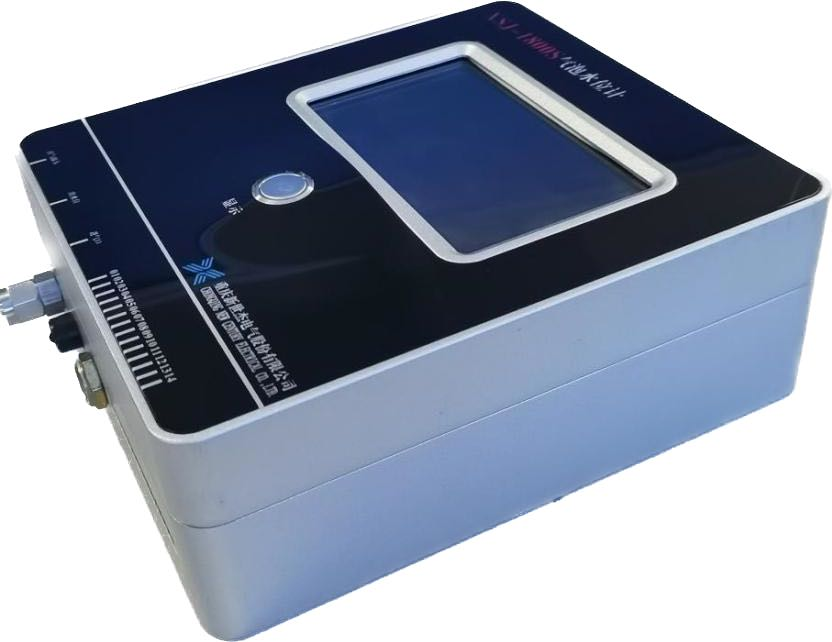

Bubble level gauge

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

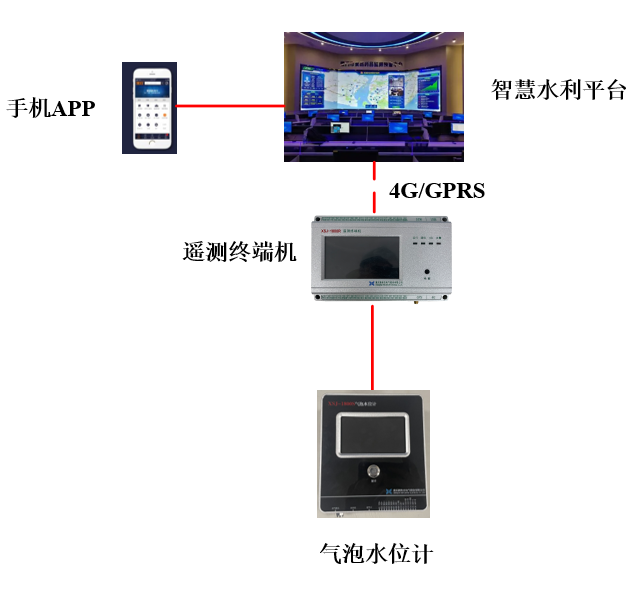

The XSJ-1800S bubble water level gauge is a high-precision water level measurement device, which belongs to an indirect measurement device based on pressure sensors and air ducts. It is mainly used for water level measurement in small and medium-sized reservoirs, river water level measurement, and drainage pipe water level measurement, etc. It is easy to install and operate, and can well meet users' needs for high precision, high stability, and high reliability of the product.

The XSJ-1800S bubble water level gauge is suitable for the following scenarios: measurement of water levels and liquid levels in rivers, lakes, reservoirs, power plants, wetlands, dams, oceans, groundwater, chemical industries, coal mines, sewage treatment, and water supply plants; it is suitable for areas where it is inconvenient to build measurement wells. For example, monitoring water levels in rivers and lakes, monitoring water levels in small and medium-sized reservoirs, monitoring water levels in urban interchanges, monitoring water accumulation on urban roads, monitoring hydrological water resource telemetry stations, monitoring water levels in urban drainage networks, and monitoring water levels in industrial control systems.

XSJ-1800S bubble water level gauge

1) Sensor anti-condensation, anti-dew design;

2) Zero point and base elevation can be freely set;

3) Built-in temperature sensor, dual temperature compensation;

4) Timed measurement, measurement and collection time can be freely set;

5) Intelligent cleaning function, automatically detects and maintains pipeline cleanliness;

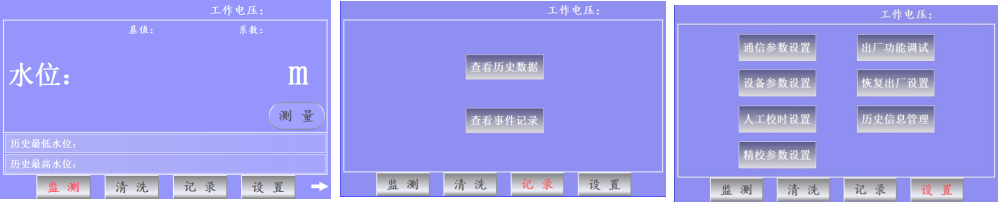

6) User-friendly touch screen display operation interface, convenient for installation and daily maintenance management;

1) Water level collection: Receive sensor data and periodically collect water level data.

2) Local storage: Locally loop-stored records of terminal historical data, not lost during power outages.

3) Device self-check: Real-time monitoring of device operating voltage, environmental temperature, air pump working status, and other information.

4) Serial communication: RS232 communication/RS485 communication/SDI communication, Modbus-RTU protocol and SDI-12 protocol.

5) Event recording: Can record various working events of the device in real time for maintenance management, currently mainly recording power information.

6) Device management: Configured with a 4.3-inch color touch screen, operations through the touch screen can achieve parameter query configuration, data reading, data clearing, factory reset, etc., and support connection to a computer configuration tool via serial communication, allowing for parameter query configuration, data reading, data clearing, factory reset, etc.

Previous:

The next one: