Smart Substation Automation System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

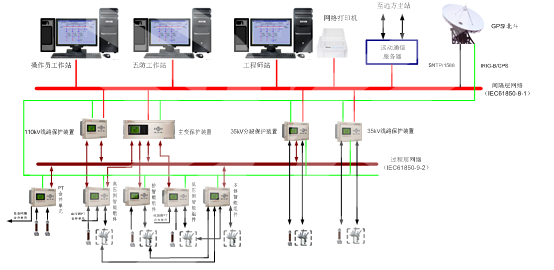

The XSJ-1500I smart substation automation system is based on improving the overall reliability of substations, utilizing various electronic transformers, switchgear, transformer online monitoring, and other technologies to achieve the intelligence of primary equipment; it employs stable and reliable synchronous sampling technology, high-flow real-time message processing, and other technologies to realize the networking of secondary equipment, achieving basic functions such as information collection, measurement, control, protection, metering, and monitoring. Through programmed operations, intelligent billing, intelligent alarms, and online analysis and decision-making technologies, it enables advanced analysis, early warning, and status maintenance functions for substations.

The XSJ-1500I smart substation automation system, based on the IEC61850 standard, provides an overall solution for the primary and secondary systems of smart substations. Following the design principles of unmanned substations, it achieves the digitalization of all station information, networking of communication platforms, standardization of information sharing, and interactivity of advanced applications, providing convenient, reliable, and intelligent services for substation operation monitoring and maintenance management, making substation operations more economical, reliable, and intelligent.

Applicable to smart substations, switch stations, etc., with voltage levels of 110KV and below.

Supports the IEC61850 standard, and the process layer and bay layer devices have fully passed the IEC 61850 conformance testing at the State Grid Electric Power Research Institute.

Supports IRIG-B, SNTP, and IEC61588 time synchronization, with a time synchronization accuracy of less than 1us.

Uses hardware parallel synchronization codec technology to process messages from various communication ports in real-time, ensuring the real-time and reliability of SV transmission and GOOSE response during full-load operation of each communication port.

The process layer interface provides sufficient optical fiber Ethernet, supporting point-to-point applications, network networking applications, and mixed applications of point-to-point and network networking.

Adopts IEC61131-3 standard modular programming technology, using graphical configuration tools to configure various protection function modules according to different requirements, automatically generating various configuration files.

Equipped with a comprehensive self-check function to achieve online monitoring of the device's own status, network status, and input/output status.

The monitoring system is suitable for Windows and Unix operating systems, with a simple and convenient human-machine interface operation; supports primary and backup server mode, single and dual network mode.

The monitoring system can achieve automatic mapping of the front-end communication model and SCADA processing model based on the full station SCD file, effectively improving system configuration efficiency.

The monitoring system adopts an integrated design of the graphic library and embeds functions such as operation tickets, integrated five defenses, and sequential control.

Relay protection function

Meet the protection function configuration for various voltage levels of smart substations; local and remote modification and verification of operating and non-operating zone settings; complete recording of protection action events, alarms, and input information; meet the timing requirements of IEC61588, IRIG-B, and SNTP.

Monitoring and surveillance function

Data and information collection and processing of various equipment information, operating information, fault recording, electrical energy, primary equipment status information, auxiliary information, etc. in smart substations; equipment and environmental image monitoring; alarm and event recording; historical data recording and display functions.

Operation control function

Local control of equipment within the substation, synchronous detection and synchronous closing, relevant logical interlocks of the entire substation system and interlocking between subsystems, supporting operation and control functions of remote centralized control centers and dispatch centers.

Intelligent advanced applications

Intelligent alarms and analytical decision-making, equipment status visualization, economic operation and optimization control, operation tickets, system diagnostics, integrated five prevention interlocks, programmatic sequential control, and other functions.

Configuration and setup function

System equipment and parameter configuration setup, graphical configuration, database configuration.

Mobile management

The system supports information publishing, human-computer interaction, and process operations through mobile terminals, achieving mobile office for the automation operation, maintenance, and management of substations.

Previous:

The next one: