Substation Integrated Automation System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

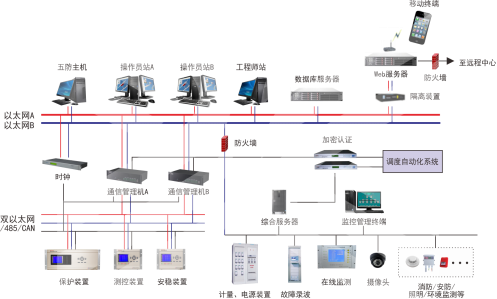

The XSJ-1500 substation comprehensive automation system is a new generation of programmable power comprehensive automation system product independently developed by the company, following the latest technical standards and specifications of the national and power industry, including the "Six Unifications" of the State Grid and the relay protection technical specifications of the Southern Power Grid, based on the IEC 61850 standard. The system adopts fully open, layered distributed, and modular design technology for both hardware and software, featuring functions such as automatic control, protection, measurement, status monitoring, self-diagnosis, visual intelligent monitoring, operational guidance, auxiliary analysis and decision-making, and remote control.

The XSJ-1500 substation comprehensive automation system is designed in accordance with the principles of "unmanned operation" and support for remote operation and maintenance, enabling economical operation, safety monitoring, intelligence, and informatization of the entire station. It can provide customers with comprehensive and integrated system solutions, helping power enterprises improve reliability, reduce operating costs, enhance labor productivity, increase safety and economic benefits, and improve the modern management level of substations, in line with the construction, operation management, and development trends of substation systems related to smart grids.

The system is suitable for substations, switch stations, etc., with voltage levels of 110kV and below.

The system adopts application software design for cross-platform operating systems such as Windows and UNIX, and commercial database application design like SQLSERVER and ORACLE, with good openness; it uses full configuration and visual programmable design technology to meet users' personalized needs.

The system employs comprehensive self-diagnosis, intelligent alarm, fault warning, and self-recovery design technology, supporting remote operation and maintenance services, improving the operational management efficiency and safety management level of power plants, and preventing equipment failures and accidents from escalating.

The system supports technical standards such as IEC61850, IEC60870-5-101, 103, 104; it supports various communication interfaces like Ethernet and RS485, as well as single network, dual network, and ring network, achieving flexible networking and information exchange and interoperability.

The human-machine interface of the monitoring system adopts graphical, three-dimensional animation, vector graphics, panoramic data information, and sequential automatic control display, meeting the user's need for simple operation and convenient use.

The monitoring system has VQC voltage reactive power adjustment function, meeting the user's needs for automatic control of voltage reactive power and economical operation.

The monitoring system uses WEB technology and Internet of Things technology, and can also utilize mobile terminals to achieve remote communication and information management of the substation system.

The relay protection system adopts a high-performance multi-CPU structure, large-capacity storage, and a 16-bit dual AD synchronous sampling algorithm, employing intelligent plug-ins, programmable logic configuration, and software and hardware filtering design technology, with important protection using dual motherboard design, ensuring high reliability and powerful functionality.

Operation Monitoring

Realize the operation monitoring and comprehensive display of information such as power grid operation information, protection information, and the operating status of primary and secondary equipment. Mainly includes operation condition monitoring, equipment status monitoring, remote browsing, etc.

Operation and Control

Realize local and remote operation control of equipment within the substation. Includes sequential control, reactive power optimization control, switch and knife switch operation under normal or emergency conditions, and anti-mislock operation, etc. The dispatch (control) center achieves dispatch control and remote browsing through data communication gateway machines. Mainly includes protection control, on-site operation, dispatch control, automatic control, anti-mislock, intelligent operation tickets, and other functions.

Information Comprehensive Analysis and Intelligent Alarm

Through comprehensive analysis and processing of real-time or non-real-time operation data, auxiliary application information, various alarm and accident signals, etc. within the substation, provide classified accident alarms, fault briefs, and fault analysis reports, etc. Mainly includes on-site data identification, fault analysis decision-making, intelligent alarms, and other functions.

Operation Management

Through manual input or system interaction, establish complete basic information of substation equipment, and realize the standardization of operation, operation, maintenance, and repair work of primary and secondary equipment. Mainly includes source end maintenance, permission management, equipment management, setting value management, maintenance management, and other functions.

Auxiliary Applications

Through standardized interfaces and information interaction, realize the monitoring and control of auxiliary equipment such as AC and DC computer power supplies, security, fire protection, video, and environmental monitoring within the station. Mainly includes power monitoring, electricity measurement, fault recording, online monitoring, safety protection, environmental monitoring, auxiliary control, and other functions.

Mobile Management

The system supports information publishing, human-computer interaction, and process operation through mobile terminals, achieving mobile office for the automation operation, maintenance, and management of substations.

Previous:

The next one: