Mobile Terminal Monitoring and Service System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

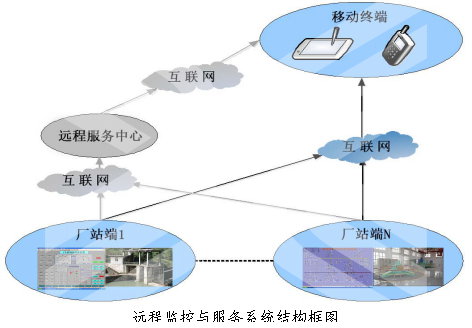

The XSJ-1000M mobile terminal monitoring and service system achieves data monitoring, video surveillance, data statistical analysis, equipment fault diagnosis and early warning, real-time operation event reporting, control parameter settings, remote operation control, and online service remote management for power plants through remote mobile terminals and station-end servers, aiming for intelligent, informational, and interactive management of power plants. The application of the XSJ-1000M mobile terminal monitoring and service system is beneficial for reducing personnel and increasing efficiency in power plants, realizing remote monitoring and remote operation and maintenance guidance, and improving the efficiency of power plant operation and maintenance management.

l convenient

The system can provide power station information and services to customers' mobile terminals anytime and anywhere, with comprehensive and multimedia display.

l efficient

Through the data, images, and videos provided by the APP, the operation status of the power station and the handling of accidents can be accurately grasped in real time, which can greatly improve efficiency and power generation benefits.

l safe

The system adopts security isolation technology, encryption authentication, and permission design to ensure the security of data communication, alleviating customers' security concerns. At the same time, equipment anomalies can be promptly warned, greatly enhancing the safety management level of the power station.

l cost-saving

The system uses dynamic resource management, requiring low hardware configuration for mobile terminals; high compression ratio data communication technology, low traffic demand, and reduced operation and maintenance costs.

l Parameter Display

Real-time display of important operating parameters and equipment status of each plant station system, safe monitoring anytime and anywhere.

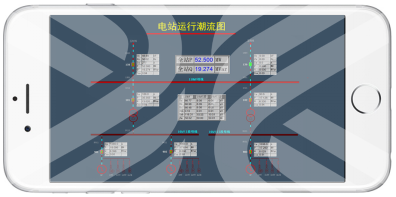

l Graphical Display

Real-time display of the power plant main wiring diagram, monitoring diagram; various curves, bar charts, or pie charts.

l Event Display

Real-time push of power plant event information, accident reports, early warning information, historical events, accident reports, and accident recording queries.

l Report Display

Retrieving and analyzing important electrical measurements, power quality, energy consumption costs, and production management reports of each power plant, assisting in the improvement of power plant operation management and supporting decision-making.

l Parameter Settings

Display of online protection settings and control parameters, and authorized online modifications, such as: setting modifications, switching of setting zones, and enabling/disabling of functional soft buttons.

l Operation Control

Authorized online operation control, such as: circuit breaker switching operations, electric isolation switch switching operations, generator start/stop operations, as well as adjustments to the generator's specified load, control of power plant power supply, fans, lighting, etc.

l Equipment Management

Online fault diagnosis of equipment, remote maintenance, equipment ledger management, equipment maintenance and testing management.

l Video Monitoring

Online remote monitoring of power plant equipment and environment, mobile detection alarms, beneficial for the safety management of the power plant and unattended operation.

l Online Services

Online contact with manufacturers, remote messaging, product online upgrades, and station maintenance expert systems, remote collaborative management of the power plant, facilitating timely technical support and quick service assurance for users.

Previous:

The next one: