Intelligent Operation and Maintenance System for Hydropower Stations

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

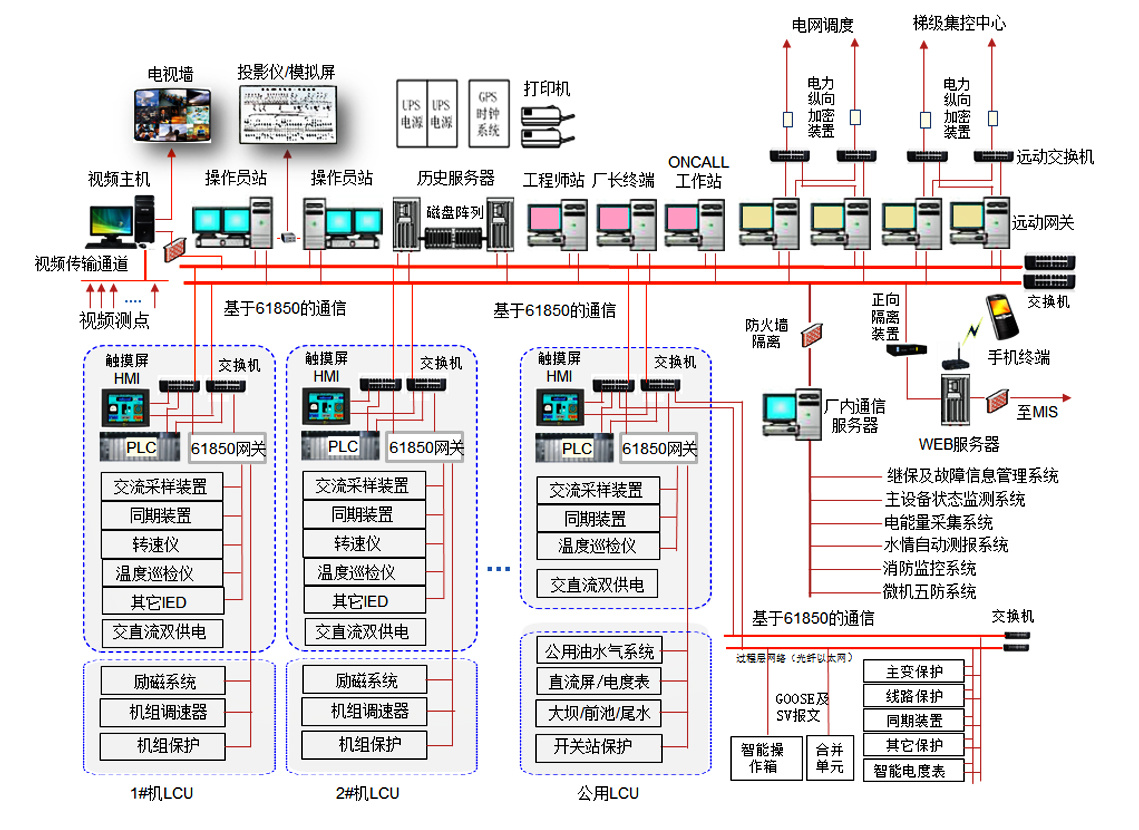

The XSJ-1300M Hydropower Station Intelligent Operation and Maintenance System is developed by the company based on the current situation of equipment and operation and maintenance management in domestic hydropower stations, as well as the technological and management development trends in hydropower stations. It follows the latest relevant standards in the fields of hydraulic engineering, hydropower, and automation, and is aimed at the integrated operation and maintenance management of hydropower stations. The system mainly includes functions such as digital twin, intelligent power generation, flood forecasting, online monitoring, fault diagnosis, equipment management, defect management, maintenance management, spare parts management, operation management, two-ticket management, safety management, technical supervision management, hydraulic management, SCADA system, inventory management, auxiliary decision-making management, document management, comprehensive office management, and mobile management, and supports the functions of the comprehensive automation system of hydropower stations through system integration.

The system is suitable for hydropower station systems with a single machine capacity of 200MW and below, as well as for the centralized control center production management of hydropower station clusters in 50 hydropower stations across regions and watersheds. It is also applicable for the production management of hydropower station cascade scheduling.

The application of the intelligent operation and maintenance system in hydropower stations is beneficial for the safe operation of hydropower stations, improving efficiency, information sharing, reducing personnel while increasing efficiency, and integrated comprehensive management. It is an important system equipment for achieving unmanned duty or unattended operation in hydropower stations, enhancing the intelligence, informatization, and modernization management level of hydropower stations.

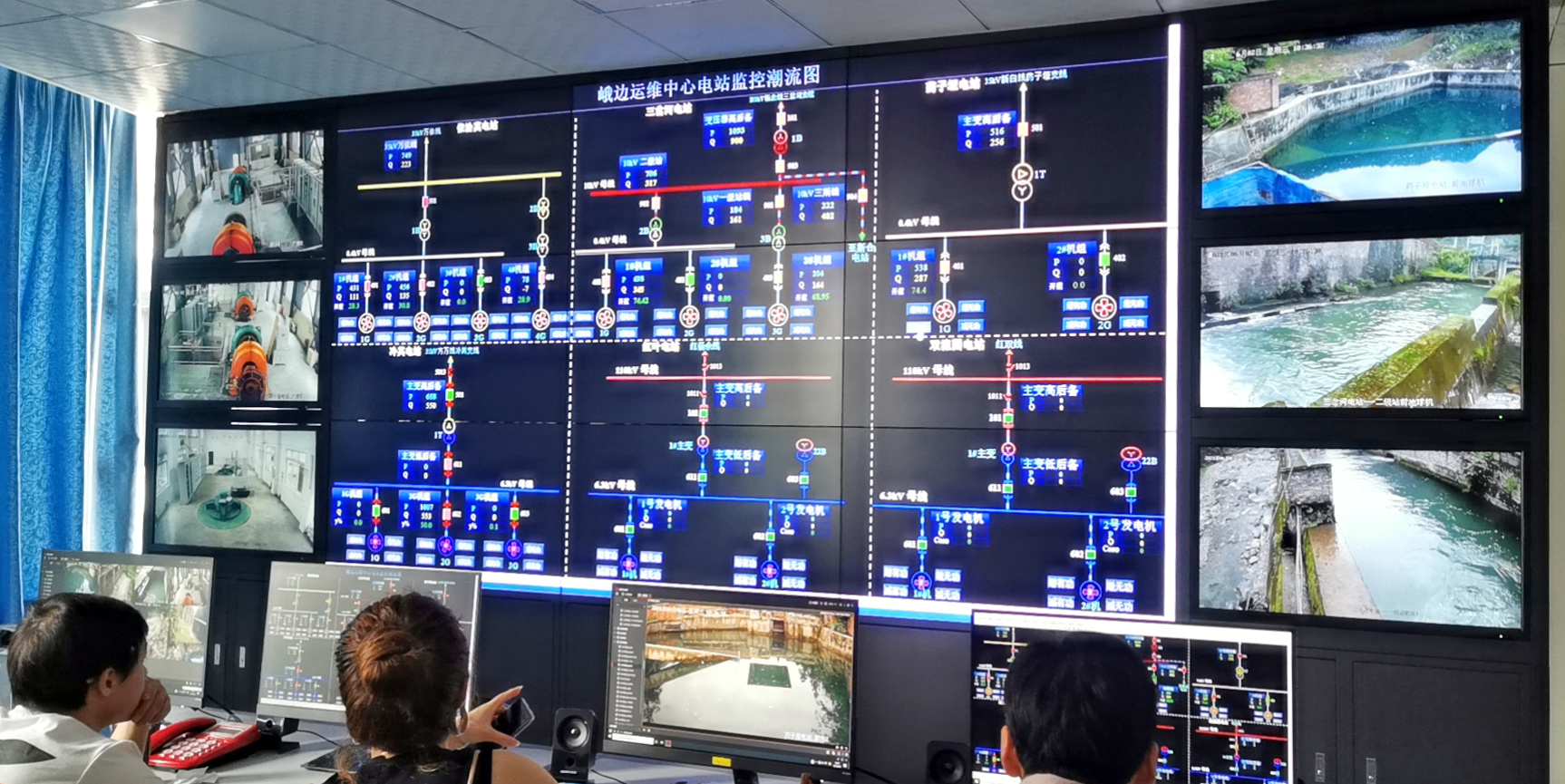

Typical application: Ebian Smart Centralized Control Operation and Maintenance Center

1) Intelligent

The system can automatically monitor various equipment in the hydropower station online, perform fault analysis and system diagnosis, and automatically alarm in case of anomalies. It can manage the operation, recording, maintenance, and health status analysis of production equipment in a streamlined manner, and interconnect with the hydropower station monitoring system, water situation reporting system, weather forecasting, security, and fire protection systems. Based on the characteristics of hydropower station production and management, it establishes intelligent comprehensive analysis for cost control, safety reliability control, and equipment maintenance, helping power station managers achieve auxiliary decision-making, automatically reminding and triggering personnel to execute management and operational tasks, realizing comprehensive monitoring and intelligent management of hydropower station operations.

2) Informational

The system has a highly integrated unified information platform that supports the integration and sharing of subsystems or functional modules such as the hydropower station relay protection system, computer monitoring system, auxiliary comprehensive monitoring system, equipment online monitoring and fault diagnosis system, equipment management, technical management, auxiliary decision-making, and mobile management. It can interconnect with the dispatch center and centralized control center, which is beneficial for improving the comprehensive management efficiency and information management level of the hydropower station.

3) Humanized

The system provides standardized and customizable workflows, with modular functionality display, rich management reports, and a panoramic human-machine interface that is easy to learn and use, greatly simplifying the complexity of user tasks and improving work efficiency.

4) Integrated

The system adopts an advanced design concept of digital twin and integrated operation and maintenance management architecture, basic platform, and application functions, supporting mainstream databases such as Microsoft SQL Server and Oracle. It fully considers the business characteristics of operations at various stages such as hydropower stations, centralized control centers, and dispatch centers, and the inherent connections between them, achieving an intelligent operation and maintenance platform for integrated operation, maintenance, and usage.

- 1) Digital Twin

By using 3D modeling, a lightweight BIM model is completed, combined with technologies such as HTML5/WebGL for display. It helps integrate building and equipment information, ensuring that various information is always integrated into a three-dimensional model information database from the design, construction, and operation of buildings and equipment to the end of the entire life cycle, facilitating collaborative work based on BIM for operation and maintenance personnel, effectively improving work efficiency, saving resources, reducing costs, and achieving sustainable development.

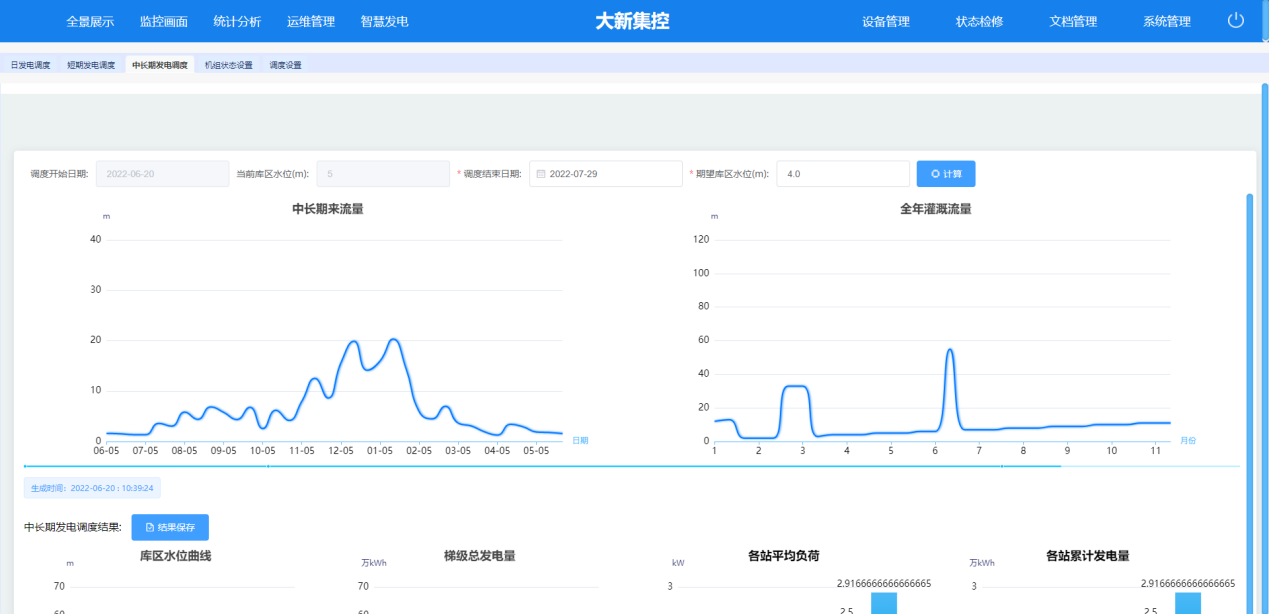

2) Intelligent Power GenerationBy predicting short-term runoff based on short-term inflow, weather rainfall, and other conditions, and using short-term runoff forecast data combined with the matching flow of each hydropower station, the scheduling goal is to maximize the cascade power generation or minimize the cascade water consumption, while also formulating the overall optimal scheduling plan for the cascade hydropower stations for the day or specified time period based on the optimized operation model of each level of power station.

2) Intelligent Power GenerationBy predicting short-term runoff based on short-term inflow, weather rainfall, and other conditions, and using short-term runoff forecast data combined with the matching flow of each hydropower station, the scheduling goal is to maximize the cascade power generation or minimize the cascade water consumption, while also formulating the overall optimal scheduling plan for the cascade hydropower stations for the day or specified time period based on the optimized operation model of each level of power station.

3) Flood Forecasting

3) Flood Forecasting

By analyzing and studying the flood characteristics of power station runoff, combined with theories of hydrology, river dynamics, etc., practical flood forecasting experience schemes and mathematical forecasting models are established; in practical applications, real-time rainfall, water conditions, and other real-time information are used as inputs, and by activating forecasting models and methods, real-time forecasts of flood peak water levels (flow), flood processes, flood volumes, and other flood elements are made, providing decision-making basis for flood control command departments at all levels.

4) Intelligent Inspection

By using IoT technologies such as QR codes, RFID, and mobile communication, combined with GIS maps, image recognition, infrared thermal imaging, etc., an intelligent inspection system that integrates manual and automatic inspections is constructed for daily inspection management of regions and equipment, achieving process-oriented business management, standardized data storage, and intelligent operation and maintenance decision-making. 5) Full Lifecycle Management

5) Full Lifecycle Management

Through a visual, refined, and user-friendly human-computer interface, aimed at production management, the entire process of equipment selection, purchase, installation, commissioning, use, maintenance, repair, transformation, updating, and scrapping is managed through database and distributed computing technology, to achieve optimal equipment lifecycle benefits and maximum comprehensive capacity in a scientific management system.

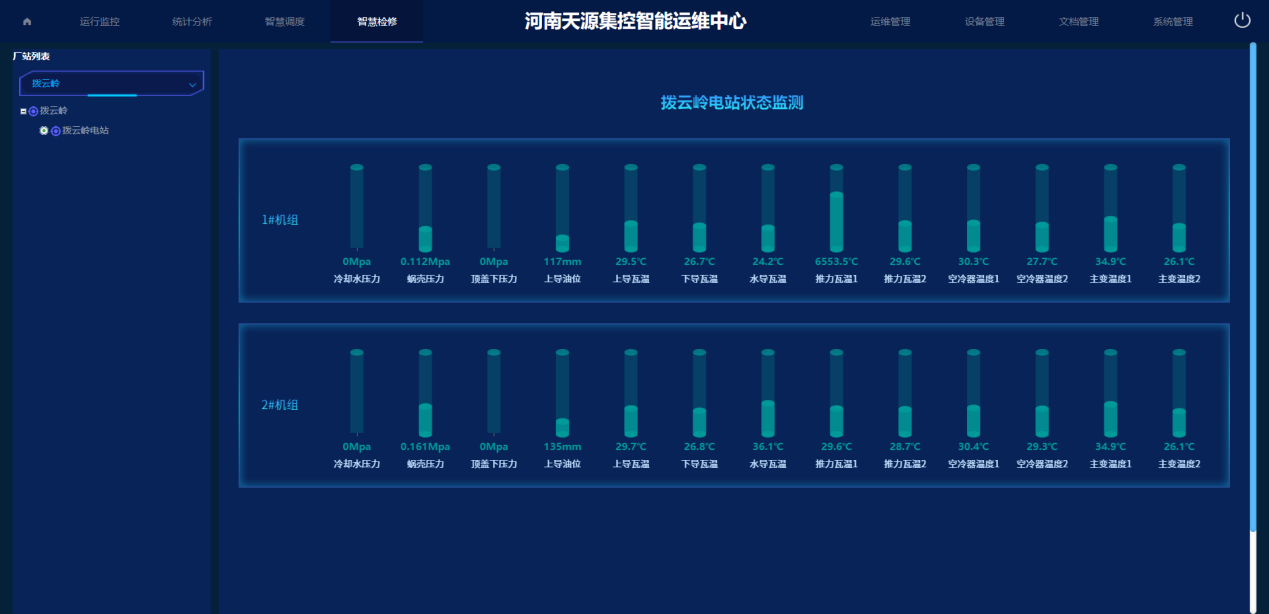

6) Equipment Status Monitoring

Including stability monitoring of hydropower units, insulation monitoring, temperature monitoring, stator grounding, rotor grounding monitoring; monitoring of overheating of the excitation regulator of generator auxiliary equipment, insulation monitoring and temperature monitoring of transformers, temperature monitoring and insulation monitoring of circuit breakers and switch cabinet busbars, cable heads, online monitoring of lightning arrester discharge current, implementing fault diagnosis and defect analysis on the status of major electrical equipment, and analyzing and warning of equipment status operation trends. 7) Fault Diagnosis

7) Fault Diagnosis

By utilizing big data technology to store and preprocess various basic data, real-time data, historical data, etc., that reflect equipment status indicators, and processing and analyzing the data according to the needs of fault warning and diagnosis, while activating fault warning and intelligent diagnosis modules to achieve early warning and diagnosis of equipment faults.

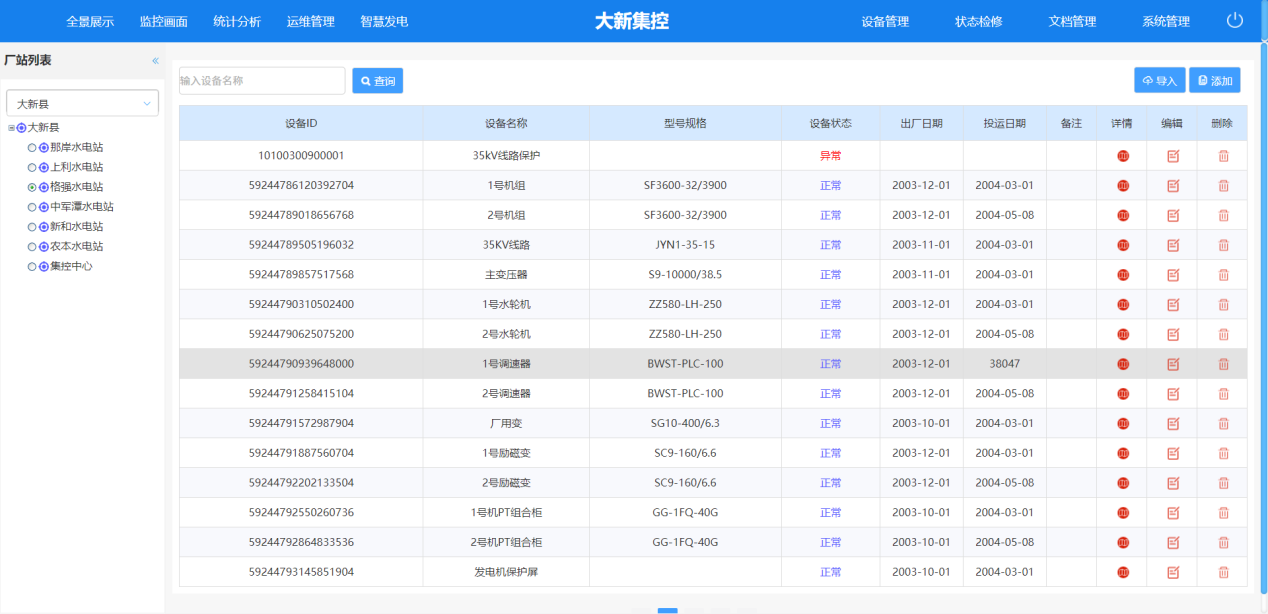

8) Equipment Management

The system establishes equipment ledger information in a tree and list dual structure, managing equipment information, basic parameters, and equipment maintenance records and queries, using computer systems to manage equipment within the power station, managing equipment health information, and allowing equipment to be used in conjunction with the KKS hydropower station coding system for equipment coding and positioning. 9) Defect ManagementThe system is designed with operational management processes and functions for discovering, recording, statistics, analysis, querying, and assessment of equipment defects.

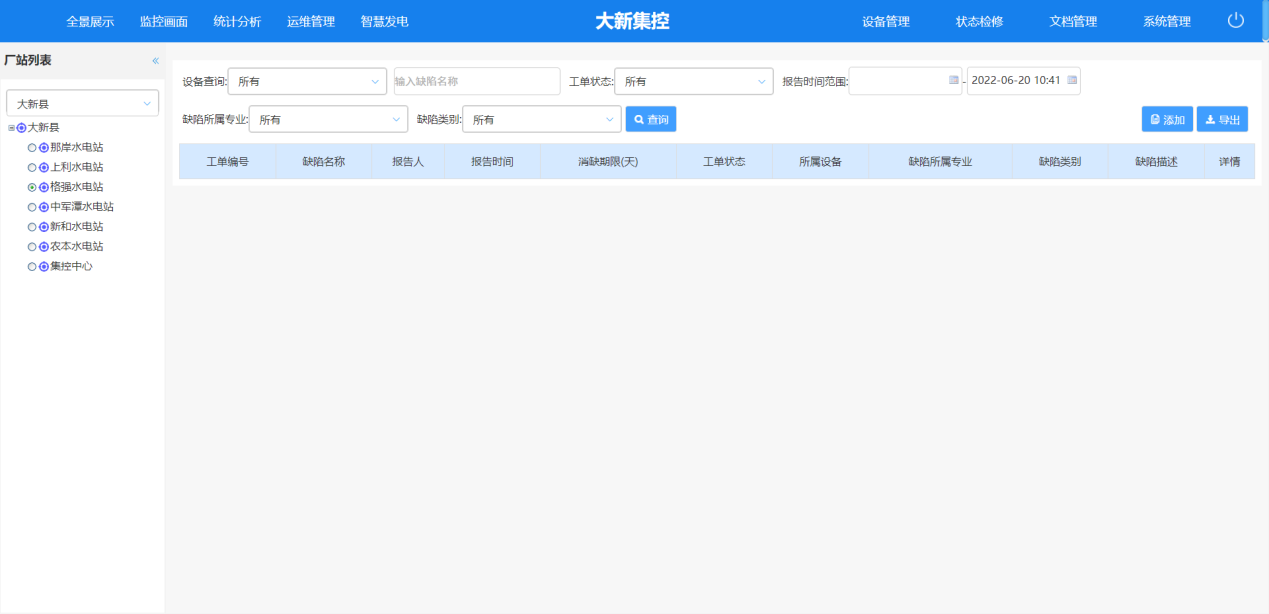

9) Defect ManagementThe system is designed with operational management processes and functions for discovering, recording, statistics, analysis, querying, and assessment of equipment defects. 10) Maintenance Management

10) Maintenance Management

The system adopts project management methods to achieve the entire process management of maintenance from planning, project establishment, implementation to acceptance. Establish a standard library for equipment maintenance projects, defining operational standards and material consumption quotas for maintenance projects in the maintenance project library.

11) Spare Parts Management

Spare parts management is linked with the system equipment ledger and material management, allowing access to all information regarding specific spare parts in the equipment ledger and material warehouse, and enabling corresponding analysis and judgment.

12) Operation Management

The system supports log management and regular work for duty and maintenance personnel, centrally standardizing the management of duty records for various operational positions, for production management personnel to query and understand power generation production conditions.

13) Two-Paper Management

The system provides a standard work ticket and operation ticket library, automatically generating and circulating two tickets based on standard tickets, supporting the filling, review, and operation of operation tickets.

14) Safety Management

The system has functions for safety standard management, two measures management, accident management, including safety planning, safety education, safety assessment, safety personnel management, and unsafe condition management.

15) Technical Supervision Management

The system establishes a technical supervision ledger, recording the operating status of various supervised equipment, recording various supervision items of equipment, and providing multiple ways to query the technical supervision situation, providing a basis for management personnel to coordinate and command production.

16) Hydraulic Engineering Management

The system establishes a ledger for hydraulic structures, recording and providing hydraulic structure information, recording hydraulic operation information and water conditions, reservoir scheduling information, providing necessary information for the daily maintenance and management of hydraulic structures and reservoirs.

17) Function Customization

The system provides screen configuration and system configuration tools, allowing customization of user monitoring screens, real-time curves, data alarms, and other functions according to user needs.

18) Inventory Management

The system supports various ledgers for warehouses and related business contents such as arrival registration, acceptance, receipt, issuance, return to stock, returns, and transfer, achieving process management of various inbound and outbound business by integrating with procurement management.

19) Auxiliary Decision-Making Management

The system has functions for indicator management, statistical analysis, and report management. It supports performance indicators for hydropower station operations, benchmarking indicators, power generation indicator analysis, economic indicator analysis, and other statistical analyses, effectively organizing and calculating historical data, forming various production statistical reports, economic indicator assessment reports, etc., helping to diagnose, assess, and improve production and operation management.

20) Station-level Communication and Remote Communication

Adopt standard interfaces to support various communication protocols, such as IEC 61850, IEC60870-5-101, 102, 103, 104, CDT, TCP/IP, and other protocols. It can achieve communication with station-level monitoring systems, power measurement systems, auxiliary integrated monitoring systems, online monitoring systems, as well as remote centralized control centers and dispatch centers, enabling data information exchange and comprehensive management of power station operations.

21) WEB Browsing Release

Use Internet browsers to implement web browsing for the hydropower station production management system. Supports remote real-time screen browsing, real-time data queries, remote report displays, historical curve queries, historical events, production information queries, etc.

22) Mobile Operation and Maintenance Management

The system supports information release, human-computer interaction, and process operations through mobile terminals, achieving mobile office for the hydropower station intelligent management system.

23) Archive Management

The system can provide electronic management of user archives, documents, and other materials for the entire power station or company.

24) Smart Office

The main functions of the system's smart office include meeting management, document handling, office supplies, schedule management, email, electronic announcements, request management, address book, work log, task management, workshop management, and file cabinets.

The next one: