Smart Water Plant Supervision System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

The XSJ-1800W-SC water plant automation system is suitable for urban and rural water supply plants. Through intelligent sensors, smart terminals, measurement and control devices, IoT communication, and cloud platform big data processing, it completes the automated monitoring and information management of water intake, purification, and distribution systems, achieving safe water supply and efficient distribution of tap water.

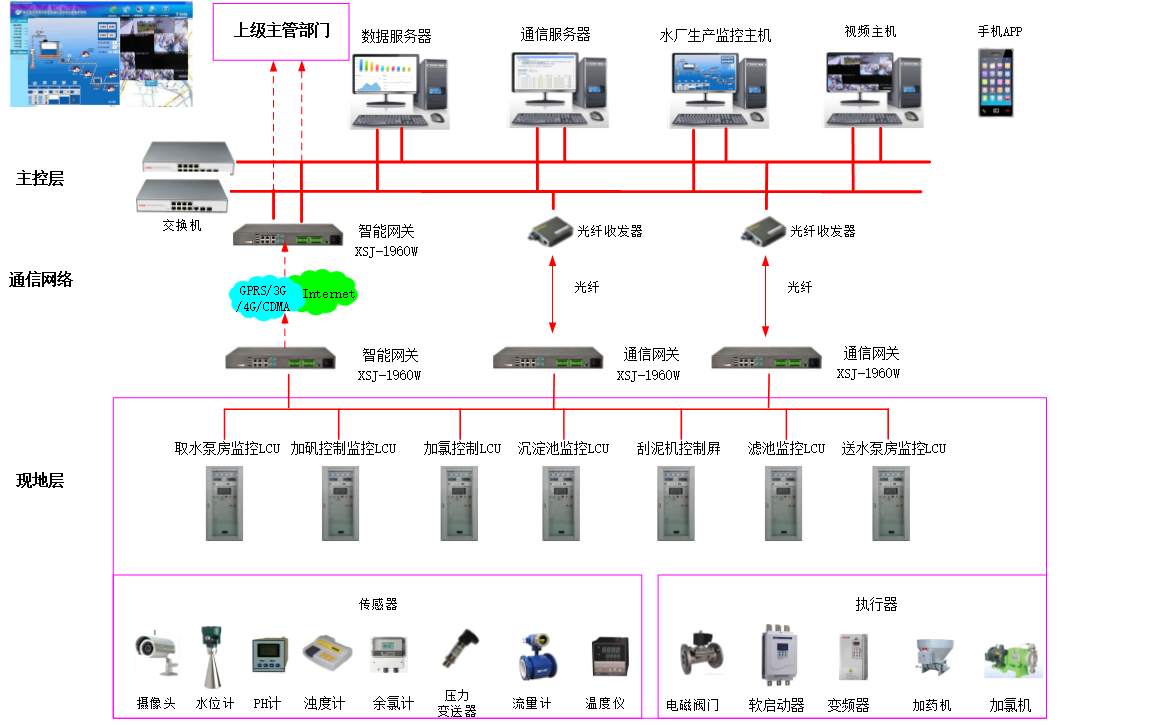

The water plant automation system consists of three parts: the field layer, communication network, and main control layer. The field layer includes various sensors for water intake, purification, and distribution, as well as water quality information collection, water quality detection instruments, smart terminals, measurement and control devices, water intake/distribution pump station monitoring LCU, water treatment monitoring LCU, etc. It is responsible for collecting data such as water level, flow, pressure, water quality, images, pumps, gate valves, and electrical parameters on-site, and transmitting this information to the main control layer through the communication network. The communication network includes various wired (electric communication or fiber optic communication) or wireless (GPRS/3G/4G, Internet, etc.) communication devices and channels, responsible for data information exchange between the field layer and the main control layer. The main control layer includes the water plant production monitoring host, servers, and other equipment, as well as the water plant monitoring system software, responsible for processing, displaying, operating, and applying the data transmitted from the field layer, achieving real-time data collection, operation monitoring, database management, operation reports and printing, online monitoring of equipment and fault diagnosis, system security management, mobile monitoring management, and other functions. The main control layer can also transmit various data information of the water plant in real-time to the higher authorities; key data such as water quantity and quality of the water supply and distribution can also be transmitted directly and in real-time to the higher authorities, achieving remote supervision services for key operational data of the water plant.

Smart Water Plant Supervision System Network Diagram

Typical Project: Automation Renovation Project of the Second Water Plant of Chongqing Fuling District Water Company - Water Plant

Project Overview: The Fuling Second Water Plant was built in 1985 and officially put into operation in 1993, covering an area of about 50 acres, providing production and domestic water for the main urban area of Fuling Jiangnan. The designed capacity is 15,000 cubic meters of water supply per day, which was expanded to 110,000 cubic meters per day in 2003, serving an area of 14.5 square kilometers and a population of 400,000. Based on current operational experience and management systems, the project includes the renovation of the dosing room, chlorination room, pre-sedimentation tank, sedimentation tank, and valve-less filter tank; construction of automatic control in the plant area and pump station, security system construction, instrument and meter construction, and renovation of the power distribution system.

1) The system is designed for the automation process of water plant production, adopting standardized processes and redundant design, meeting the technical specifications of the water plant, with a high degree of automation, ensuring user safety and convenience.

2) The system uses distributed intelligent sensors, Internet of Things technology, visual processes and operational control, as well as integrated design for online equipment monitoring, employing self-diagnosis, fault warning, and system self-recovery design technologies to meet users' requirements for visualization, intelligence, and information management.

3) The system employs intelligent variable frequency energy-saving technology, online water quality detection and analysis, and automatic dosing neural networks, genetic algorithms, fuzzy control, etc., to meet users' management requirements for water conservation, energy saving, medication saving, and water quality safety.

4) The system software supports monitoring data video linkage, using graphical configuration, visual sequential control, and 3D animation design technology for simulating water plant production processes, showcasing panoramic data and image information, providing operational guidance and error-proof locking, with a user-friendly human-machine interface that meets users' personalized usage requirements.

5) The system's intelligent devices use strong and weak current isolation, with all intelligent terminals adopting a fully sealed design, and all interfaces employing optoelectronic isolation and lightning protection design technologies to ensure the safe and reliable operation of system equipment, capable of adapting to relatively harsh environments.

6) The system can utilize broadband, mobile Internet communication, and cloud platform data services with network security isolation, using WEB servers and mobile terminals to achieve Internet communication and comprehensive information management for the water plant automation system.

1) Operating environment parameters

Ambient temperature: -20 to 50℃, allowable relative humidity: ≤90%

2) Measurement error of parameters: ≤±0.5% (depends on the selected acquisition sensor)

3) Control and adjustment accuracy: 100%

4) Electrical quantity acquisition cycle: ≤1s

5) Non-electrical quantity acquisition cycle: ≤2s

6) Status and alarm point acquisition cycle: ≤100ms

7) Event record resolution time: ≤2ms

8) Data transmission time of changes collected by LCU to real-time database: ≤1s

9) Response time of LCU receiving control commands: ≤1s

10) Response time for calling a new screen: ≤1s

11) Dynamic data refresh time on displayed screen: ≤1s

12) Response time of main control level control function: ≤1s

13) Time from alarm or accident occurrence to sound output on screen display: ≤1s

14) System availability: ≥99.9%

15) Mean time between failures (MTBF): 60000 hours

1) Real-time Data Collection

Real-time collection and monitoring of various data from the water plant, such as water level, water quality, flow, pressure, water treatment, and equipment status.

2) Operation Monitoring

On-site/remote and manual/automatic control of pumps, gate valves, dosing equipment, electrical equipment, sequential control, one-click start and stop, cooling water monitoring, etc.

3) Database Management

Recording, saving, checking, analyzing, processing, and calculating the data, images, and other information collected from the entire plant's production and operational equipment, updating relevant data to the database, including real-time and historical databases.

4) Operation Reports and Printing

Supports standard or customized various operational data reports and records, automatically generating and printing various reports and operation logs on a schedule or on demand. Users can select by year, month, or day to query various historical reports on water plant operation management.

5) Online Monitoring and Fault Diagnosis of Equipment

Configurable online monitoring and fault diagnosis system for key equipment such as pump groups, switches, dosing equipment, gate valves, and pipelines, as well as self-diagnosis of automation devices like PLCs and smart sensors, achieving online monitoring and fault diagnosis functions for major equipment in the water plant.

6) System Security Management

Setting and managing parameters related to the reservoir flood control scheduling automation system, including user management, reservoir settings, system menu customization, and system parameter settings.7) WEB News

Supports remote real-time screen browsing, real-time data queries, remote report display, historical curve queries, historical event queries, etc. Web browsing of the water plant production process can be achieved using an Internet browser.8) Mobile Monitoring Management

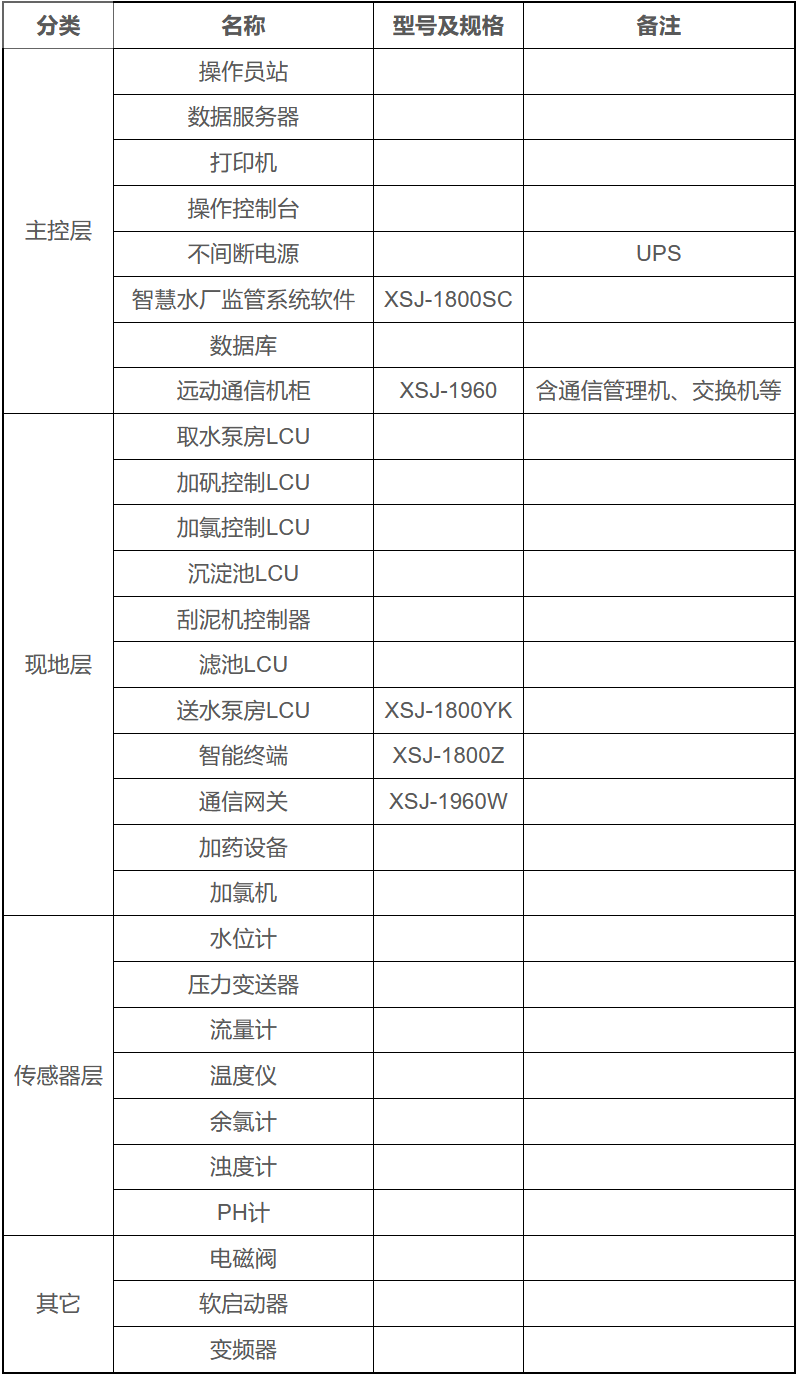

Supports Mobile APP applications, enabling screen browsing, data viewing, event queries, fault warnings, and accident handling guidance.WisdomThe equipment of the smart water plant supervision system will have different configurations, installation requirements, and system integration application methods based on the construction or renovation scope, scale, technical requirements, and investment of the water plant. The following is a brief list of the main types of equipment based on the automation design requirements of a medium-sized water plant, which serves only as a reference for the selection of system equipment for water plant projects.

Typical equipment configuration of the smart water plant supervision system

Previous:

The next one: