Smart Pipeline Supervision System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

The XSJ-1800W-GW water supply pipeline monitoring system is suitable for water supply stations, water source wells, water plants, and water supply pump rooms. Through intelligent sensors, telemetry terminals, and IoT communication, it completes automatic monitoring and remote supervision management of the water supply pipeline, ensuring the safe operation and efficient management of the water supply pipeline system.

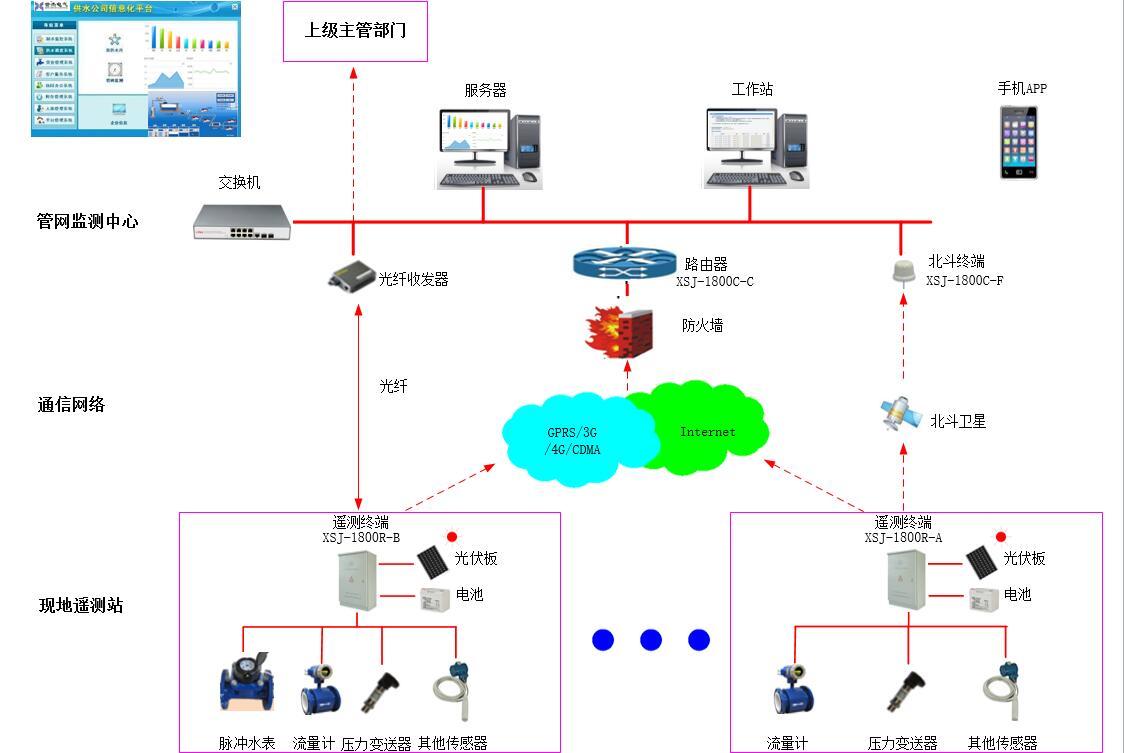

The water supply pipeline monitoring system consists of three parts: the on-site telemetry station, communication network, and pipeline monitoring center. The on-site telemetry station includes various sensors for collecting water supply pipeline information, telemetry terminals, solar power supply, and other equipment, responsible for collecting data on site such as water level, flow, pressure, water quality, pump gates, and electrical data, which is transmitted to the pipeline monitoring center through the communication network. The communication network includes wired (electrical communication or fiber optic communication) or wireless (GPRS/3G/4G, Internet, etc.) communication devices and channels, responsible for data information exchange between the on-site telemetry station and the pipeline monitoring center. The pipeline monitoring center includes monitoring workstations, servers, and water supply pipeline monitoring system software, responsible for processing, displaying, operating, and applying various data information transmitted from the on-site measurement station, achieving functions such as pipeline map information, real-time data monitoring, data comprehensive management, fault warning management, and mobile monitoring management. The pipeline monitoring center can also transmit water supply pipeline data information in real-time to higher-level supervisory departments or achieve remote supervision and service of the water supply pipeline through cloud data servers.

Smart Pipeline Supervision System Network Diagram

1) The water supply pipeline monitoring system adopts a distributed monitoring sensor and an open data interface design principle, meeting technical specifications.

2) The water supply pipeline monitoring system combines a dustproof and moisture-proof integrated screen cabinet with distributed intelligent sensors, providing powerful functionality and reliable performance, meeting the requirements for remote monitoring management in an unmanned field.

3) The segmented design of pipeline measurement points for pressure and flow sensors allows for real-time online monitoring of the normal working status of the water pipes, as well as abnormal issues such as pipe bursts, leaks, and blockages, facilitating the safe management of water supply and pipelines.

4) The monitoring terminal features a rich and standardized communication interface, supporting various communication methods such as GPRS/3G/4G, Internet, NB-IoT, and LoRa. It can also utilize mobile terminals to achieve remote monitoring and comprehensive information management of the pipeline system.

5) The monitoring terminal employs strong and weak current isolation and a fully sealed design, with optical isolation and lightning protection technology used for each interface, ensuring the safe and reliable operation of system equipment, capable of adapting to relatively harsh environments.

1) Operating environment parameters

Ambient temperature: -20 to 50℃, allowable relative humidity: ≤90%

2) Measurement error of parameters: ≤±0.5% (depends on the selected acquisition sensor)

3) Control accuracy: 100%

4) Electrical quantity acquisition cycle: ≤1s

5) Non-electrical quantity acquisition cycle: ≤1s

6) Status and alarm point acquisition cycle: ≤100ms

7) Event record resolution time: ≤2ms

8) Data transmission time of changed data collected by the smart terminal to the real-time database: ≤1s

9) Response time for the smart terminal to accept control commands: ≤1s

10) Response time for calling a new screen: ≤1s

11) Dynamic data refresh time on the displayed screen: ≤1s

12) Response time for main control level control functions: ≤1s

13) Time from alarm or incident occurrence to sound output on the screen: ≤1s

14) Mean time between failures (MTBF): 50000 hours

1) Map Information

Query and browse the geographical location information of each measurement station, pipeline water information, key operating parameters, equipment information, etc. through the GIS geographic information system.

2) Real-time Data Monitoring

Comprehensive collection, processing, and monitoring of data such as pressure, flow, and water quality of the water supply pipeline network, as well as the operating status of distribution equipment.

3) Data Comprehensive Management

Statistical analysis, classification calculation, database storage and recording of operational data such as water quality, pressure, flow, water fees, and equipment self-checks of the water supply pipeline network, along with graphical presentation of data and graphics through pipeline maps, water supply reports, curves, bar charts, and pie charts. In case of data anomalies, automatic abnormal information is sent to on-duty personnel and management for information reminders and early warning processing.

4) Data Communication Function

The monitoring data of the water supply pipeline network has various communication data interfaces, supporting remote monitoring or control functions through communication connections.

5) Fault Warning Management

Safety monitoring and video surveillance of the water supply pipeline network, anti-theft alarm. It can detect abnormal status information such as pipe bursts, leaks, and blockages, and can link to automatically control pumps or valves for safety management.

6) Mobile Monitoring Management

The system supports Mobile APP services, enabling monitoring of data such as water level, flow, pressure, water quality, power, and accident information at various pipeline measurement points. This allows users to monitor and manage the water supply pipeline network system anytime and anywhere.

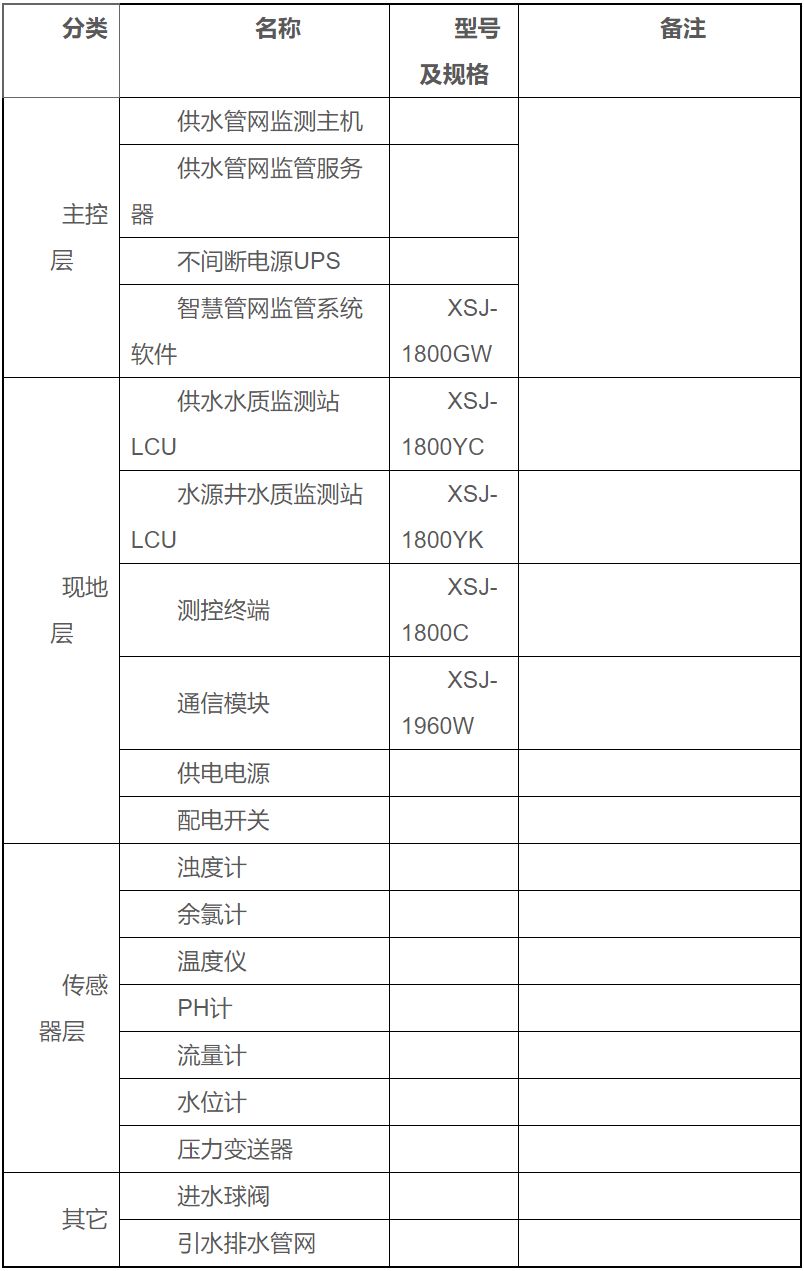

The smart pipeline monitoring system equipment will have different configurations, installation requirements, and system integration application methods based on the specific project's water supply pipeline construction or renovation scope, scale, technical requirements, and investment. The following lists the main types of equipment required for a medium-sized water supply pipeline monitoring system design as a reference for equipment selection.

The next one: