Smart Agricultural Drinking Supervision System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

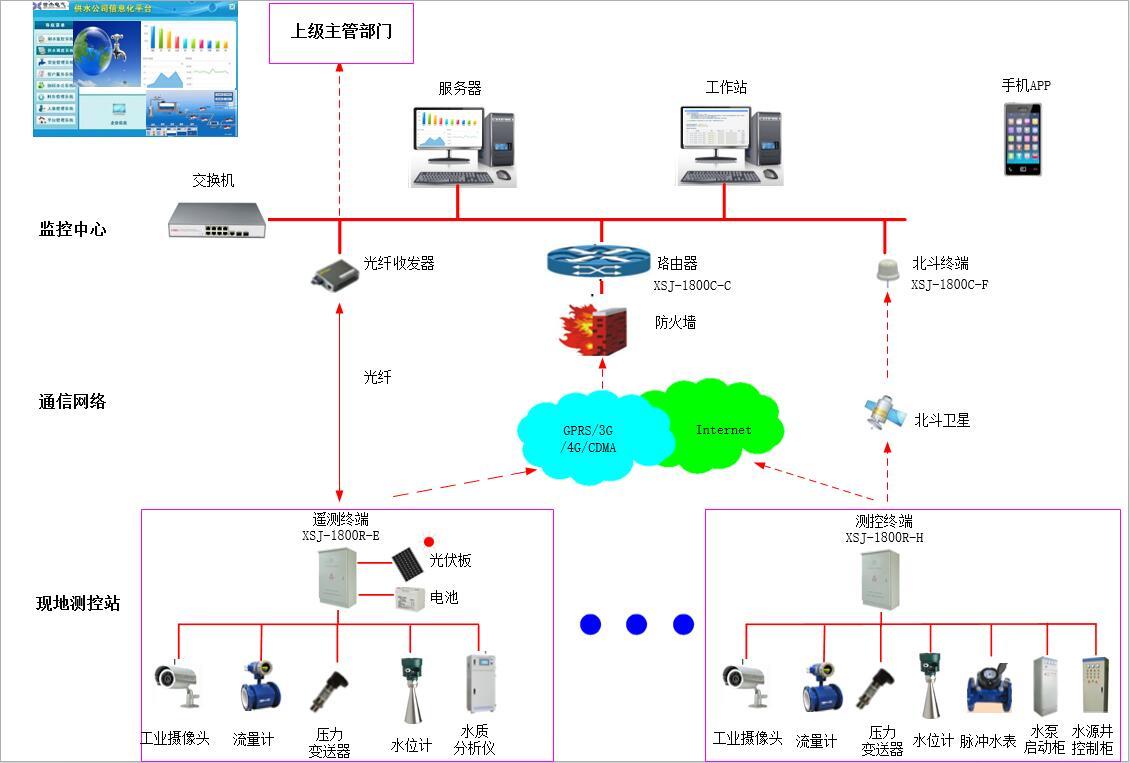

The Smart Agricultural Drinking Water Supervision System is suitable for rural water supply stations, water source wells, and water conservancy bureaus. It consists of a monitoring center station and multiple measurement and control water supply stations, achieving functions such as water quality monitoring of each water station, water supply information management, data collection and processing, data record inquiry, data statistical analysis reports, system early warning and alarm, display of water station process diagrams, control of terminal equipment (including starting, stopping, and pressure adjustment), terminal operation planning, etc. It also realizes advanced functions such as remote fault diagnosis of water pumps at each water station, remote switching of water pumps, and self-learning intelligent energy-saving control.

The Smart Agricultural Drinking Water Supervision System addresses the challenges of insufficient management personnel and weak technology in the water conservancy bureaus of various districts and counties. It can meet the safety and efficiency of rural drinking water and monitoring management, facilitating real-time monitoring of rural drinking water safety implementation and operation by the water management departments of various districts, counties, or cities, achieving vertical management at the provincial, municipal, and county levels, and enhancing the modernization management level of rural drinking water safety by the water bureaus of various districts and counties.

Smart Agricultural Drinking Water Supervision System Network Diagram

Typical Project: Online Water Quality Monitoring Transformation of Youyang Dingshi Water Plant

Project Overview: Dingshi Water Plant is a key water plant for rural drinking water in Dingshi Town, Youyang, responsible for the daily water supply of residents in Dingshi Town. This project involves a deep transformation of online water quality monitoring and automation of the water plant, achieving unmanned automated operation of the agricultural drinking water plant.

1) The water supply station's measurement and control system uses a dustproof and moisture-proof integrated screen cabinet combined with distributed intelligent sensors, meeting the requirements for remote monitoring and management in an unmanned field.

2) Each intelligent device at the measurement and control station adopts strong and weak current isolation and sealed design, with automatic heating and dehumidification. Each interface uses photoelectric isolation and lightning protection design technology to ensure the safe and reliable operation of the equipment, capable of adapting to relatively harsh environments.

3) The measurement and control station is designed with video and anti-theft functions, as well as status monitoring and fault diagnosis functions for pumps and inverters. It can monitor the normal working status and abnormal alarms of the water supply and pump equipment in real-time through a remote monitoring center, facilitating the safe and efficient management of the water supply station.

4) The monitoring center can also access the mobile internet through a Mobile APP, enabling mobile monitoring and management of the water supply station, allowing personnel from the supervisory department or water authority to grasp the operational status of the water supply station anytime and anywhere, assisting in management.

1) Operating environment parameters

Ambient temperature: -20 to 50℃, allowable relative humidity: ≤90%

2) Measurement error of parameters: ≤±0.5% (depends on the selected acquisition sensor)

3) Control accuracy: 100%

4) Electrical quantity acquisition cycle: ≤1s

5) Non-electrical quantity acquisition cycle: ≤1s

6) Status and alarm point acquisition cycle: ≤100ms

7) Event record resolution time: ≤2ms

8) Data transmission time from the measurement and control terminal to the real-time database: ≤1s

9) Response time for the measurement and control terminal to accept control commands: ≤1s

10) Response time for calling a new screen (90% of screens): ≤1s

11) Dynamic data refresh time on the displayed screen: ≤1s

12) Response time for main control level control functions: ≤1s

13) Time from alarm or incident occurrence to sound output on the screen: ≤1s

14) Mean time between failures (MTBF): 60000 hours

1) Real-time monitoring of water supply inflow and outflow, outflow pressure, water tank water level, residual chlorine water quality, and other data information.

2) Real-time monitoring of the working status of the chlorinator, chlorination speed, and the start/stop of automatic control/remote control of the chlorinator.

3) Real-time monitoring of the working condition of the water source well pump, including current, voltage, electrical energy, pump switch status, protection status, outflow pressure, and outflow rate. The water source well pump can be started and stopped remotely.

4) Real-time monitoring of the working status of the booster pump group, including switch status, protection status, voltage, current, frequency, water pressure, flow rate, etc.

5) On-site automatic control and remote control of the start/stop of the booster pump. Automatically adjust the pump speed based on outlet pressure to achieve safe and effective water supply.

6) Real-time monitoring of the electrical equipment status information of the water supply distribution station, including: switch status, current, voltage, electrical energy, etc.

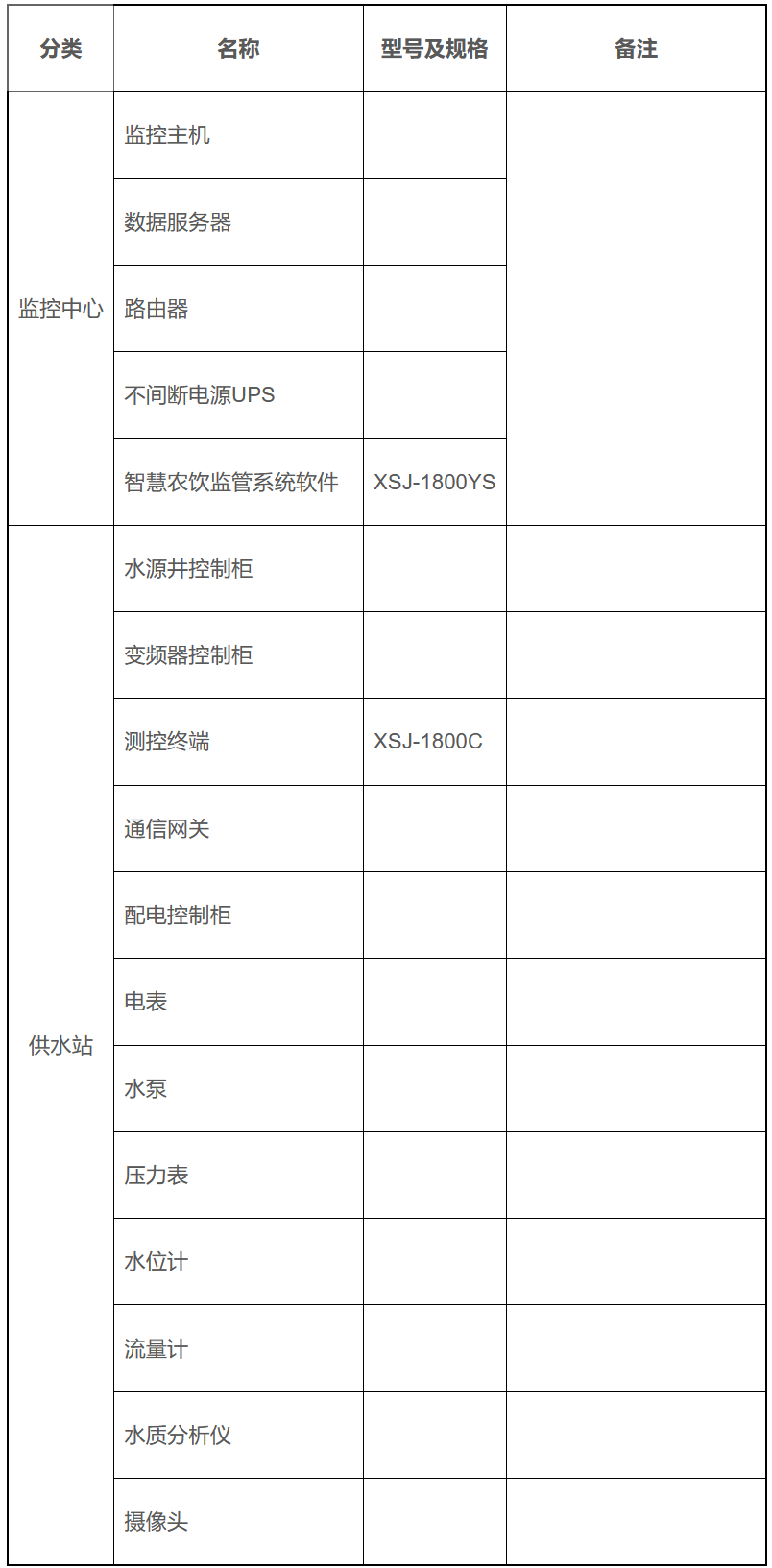

Smart Agricultural Drinking Supervision SystemThe equipment will have different configurations, installation requirements, and system integration application methods based on the project's construction or renovation scope, scale, technical requirements, and investment. The following is only a reference for the selection of equipment for the rural drinking water safety supervision system.

Typical Equipment Configuration of Smart Agricultural Drinking Supervision System

Previous:

The next one: