Intelligent Water and Power Station Supervision System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

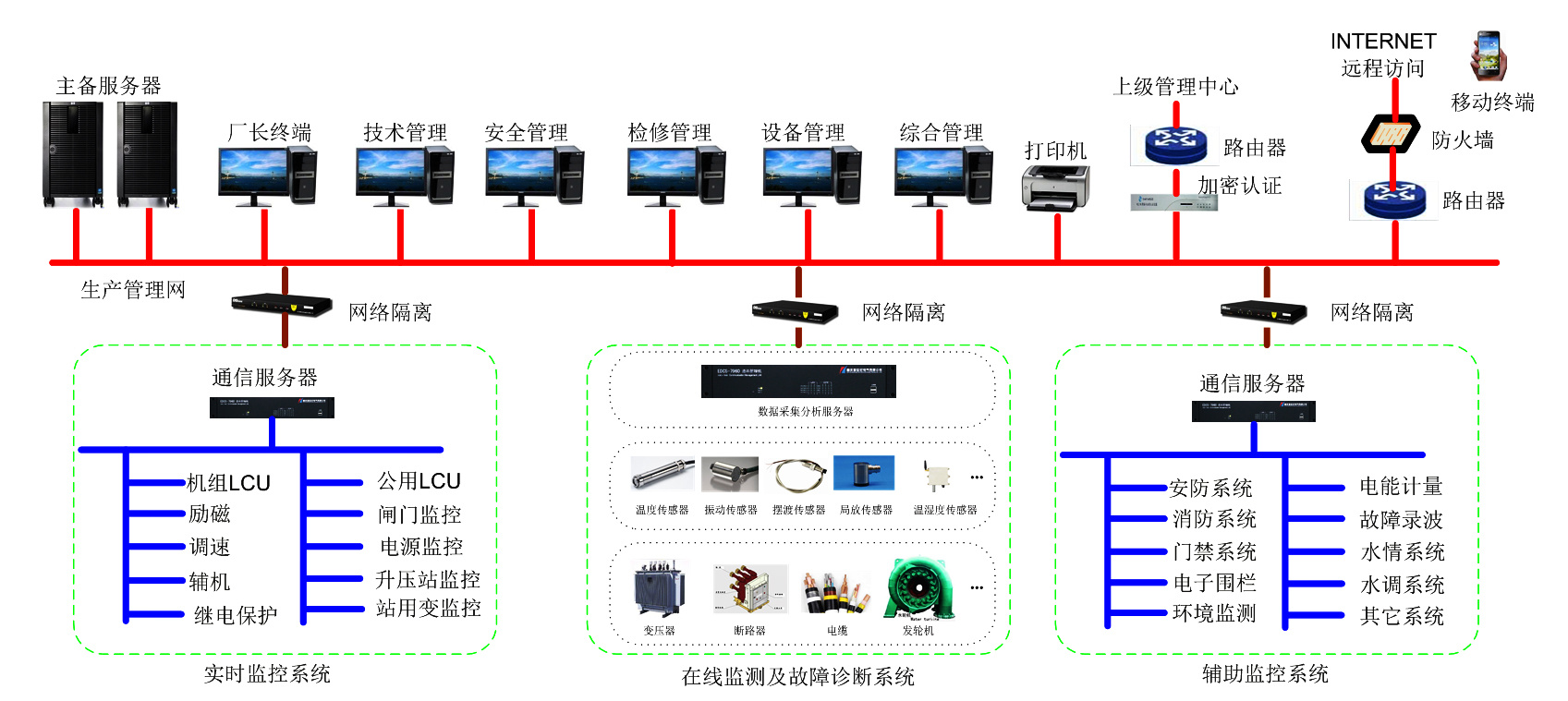

The intelligent hydropower station monitoring system is a new generation of comprehensive automation system products that comprehensively applies technologies such as smart grids, the Internet of Things, modern communication, and computers. It is based on the national grid's "six unifications" and the new standards of the Southern Power Grid protection specifications, combined with the company's years of technical experience. The system adopts a fully open, layered distributed, modular structure that complies with the latest international and domestic standards, as well as object-oriented systematic design technology.

The intelligent hydropower station monitoring system is designed according to the operational management principles of "unmanned operation" for hydropower stations. It features data collection and processing, safety monitoring, relay protection, unit sequence control, operational adjustment, interface configuration, simulated light signboards, database management, data statistics and report printing, intelligent voice alarms, automatic Tel alarms and inquiries, accident recall, error prevention, operation ticket management, operational guidance, clock synchronization, system self-diagnosis and self-recovery, WEB browsing and publishing, station-level communication and remote communication, and mobile management, supporting remote monitoring and operation and maintenance management of the centralized control center and dispatching system.

The system is suitable for hydropower station systems with a single machine capacity of 200MW and below, as well as unmanned or unattended and intelligent hydropower station systems.

The application of the intelligent hydropower station monitoring system is beneficial for reducing personnel and increasing efficiency, improving the reliability and safety of the hydropower station automation system, and achieving the intelligent, informational, and modernized operation, maintenance, and management of the entire power station.

Typical application: Dayan Pit Hydropower Station

1) The monitoring system adopts application software design for cross-platform operating systems such as Windows and Linux, as well as commercial database application design using SQLSERVER and ORACLE, balancing reliability and convenience.

2) The system supports technical standards such as IEC61850, IEC61970, and IEC61131; it fully supports communication interfaces like Ethernet, CAN, and RS485, as well as dual network and ring network requirements, enabling flexible system communication networking and information exchange, as well as interoperability.

3) The protection system follows the national grid's "six unifications" and the Southern Power Grid's relay protection design specifications, ensuring high reliability and powerful functionality.

4) The monitoring system also uses a comprehensive control device for units that integrates functions such as AGC, AVC, EDC, and automatic power generation based on water levels, ensuring high reliability in coordinated control of hydropower station units, with quick and sensitive operational adjustments.

5) The system employs Internet of Things technology to achieve self-diagnosis and self-recovery of equipment, system fault diagnosis, and fault early warning, improving the safety management level of the power station and preventing equipment failures and accidents from escalating.

6) The human-machine interface of the monitoring system uses graphical, three-dimensional animation, vector graphics, and panoramic data information display, meeting the user's needs for simple operation and convenience.

7) The monitoring system utilizes WEB technology and mobile terminals to achieve remote communication and information management for hydropower station systems.

1) Data Collection and Processing

The system automatically collects various electrical quantities, switch quantities, non-electrical quantities, and pulse quantities of the power station's real-time operating parameters and operating status periodically or randomly, records, saves, checks, analyzes, processes, and calculates the collected data, and updates the relevant data to the database, including real-time databases and historical databases.

2) Safety Monitoring Function

The system has event and accident display records, equipment operation records, operator command information records, computer system operation and self-check information records, trend analysis and alarm (real-time quantity change rate trend analysis judgment) functions.

3) Intelligent Protection Function

Based on the national grid's "Six Unifications" and the Southern Power Grid relay protection design specifications, it implements protection for the power station's lines, main transformers, generator units, and other equipment and power systems, and has self-diagnosis and self-recovery functions for protection devices.

4) Unit Sequence Control

Provides an intuitive and convenient graphical sequence control process, supporting single-step, breakpoint, continuous execution modes. It has a one-click start-stop function, remote/local monitoring, and operation permission password management to ensure safety.5) Intelligent Power Generation Function

The system supports various adjustment operation modes, such as Automatic Generation Control (AGC), Automatic Voltage Control (AVC), Economic Operation Mode (EDC), and automatic power generation based on water levels.

6) Interface Configuration FunctionIt has a rich library of power system symbols, can automatically add and edit graphic elements. Users can create human-machine interfaces according to their habits, which are easy to master and convenient to use. It supports screen copying, screen linking, and screen playback functions.

7) Simulation Light Sign Function

Provides flexible "accident light sign" display, query, confirmation, and alarm functions, with different types of "light signs" (accident or fault) defined by different colors.8) Database Management Function

The relational historical database uses mainstream commercial databases such as Microsoft SQL Server/Oracle, and can also choose file databases, supporting historical curve display, historical event record queries, switch action counts, and cumulative operating time statistics. Its operational historical data and related statistical data can be used by operation, management, and maintenance personnel for accident analysis.

9) Data Statistics and Report Printing

Various operational data reports and records can be customized, automatically generated, and printed on schedule or on demand. Users can select by year, month, and day to query various historical reports, and can also implement operation ticket printing, using a tree directory for quick and convenient queries.

10) Intelligent Voice Alarm, Automatic Tel Alarm and Query

The system has intelligent alarm functions, providing priority-based Tel, paging, Mobile APP, and voice alarms, as well as accident handling guidance.

11) Accident Recall

Replays the time period before and after the accident, displaying the entire process of the accident, facilitating post-accident analysis.

12) Error Prevention

Customizable locking logic is available, with electrical error prevention, circuit breaker fault locking operations, setting isolation switches, and locking circuit breaker operations.

13) Operation Ticket Management

It has automatic filling, recording, querying, and printing functions for operation tickets, and can guide operation steps correctly based on operation tickets, automatically executing abnormal alarms.

14) Operation Guidance

Based on the power plant's operating conditions, it provides relevant problem queries and guidance, and offers simulation training for operating personnel.

15) Clock Synchronization

The computer monitoring system should be able to correctly receive GPS clock information and achieve clock synchronization among various nodes within the system.

16) System Self-Diagnosis and Self-Recovery

The computer monitoring system can perform self-diagnosis of hardware and software within the system during online operation. When a fault is diagnosed, it automatically sends a signal, and for redundant devices, it can automatically switch to backup devices; self-recovery functions include monitoring timers (watchdogs) and self-start functions for software and hardware; power failure protection functions.

17) WEB Browsing Release

Using Internet browsers to achieve Web browsing of the hydropower station monitoring system. Supports remote real-time screen browsing, real-time data queries, remote report displays, historical curve queries, and historical event information queries.18) Station-Level and Remote Communication

Using standard interfaces, supporting RS232, RS485, industrial field buses, and Ethernet communication interfaces. Supports various communication protocols such as IEC 61850, IEC60870-5-101, 102, 103, 104, CDT, TCP/IP, etc. Achieves communication with station-level systems such as online monitoring and fault diagnosis systems, water conditions, security, fire protection systems, as well as remote communication with the centralized control center and dispatch center, sending specified power station operation information and receiving and executing issued plant commands.

19) Mobile Operation and Maintenance Management

The system supports information News, human-machine interaction, and process operations through mobile terminals, achieving mobile office for the automation operation, maintenance, and management of hydropower stations.

Previous:

The next one: