Smart Dam Supervision System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

The smart dam monitoring system collects relevant data that affects dam safety through various monitoring sensors on the dam, performs data algorithms, processing, statistics, and analysis, and achieves monitoring of dam deformation, displacement, pressure, seepage, and water conditions. It forms a data and automatic reporting information system for the safe operation of the dam, which is used by the dam safety management authorities to implement efficient safety management. The smart dam monitoring system mainly consists of monitoring management stations and monitoring terminals, realizing functions such as data collection, data processing, data communication, and remote management. The application of this system can provide efficient and accurate real-time data for the dam safety authorities, simplify management, improve efficiency, and enhance the level of dam safety management.

The smart dam monitoring system is suitable for occasions such as hydropower plant reservoirs, rivers, and pond dams, including types of dams such as earth dams, earth-rock mixed dams, concrete dams, and masonry dams.

Typical project: Research and application technology service project for automatic monitoring technology of seepage and seepage pressure of the dam at Heilongjiang Lianhua Power Plant.

Project overview: Lianhua Power Plant is located at the junction of Mulanji Village in Sandaohezi Township, Hailin City, Heilongjiang Province, China, and Lianhua Village in Linkou County, with a total reservoir capacity of 4.2 billion cubic meters, making it the largest hydropower station in Heilongjiang Province. The stone dam is 902 meters long, with a maximum dam height of 71.8 meters, an installed capacity of 550,000 kilowatts, and a designed annual power generation of 797 million kilowatt-hours, primarily for power generation, with benefits for flood control, irrigation, navigation, and aquaculture.

The original automatic monitoring system for seepage and seepage pressure of the Lianhua Power Plant dam is no longer functioning properly. This includes damage to the piezometer in the pressure pipe, pipe protection devices, flow measurement weirs, and data collection devices (MCU), all of which are damaged to varying degrees, leaving the system essentially paralyzed and unable to provide timely, accurate, and effective monitoring data for the daily operation of the dam, posing potential safety risks. Given the national grid's emphasis on dam safety and the significant accidents and economic losses caused by dam safety issues in recent years, the renovation of the seepage and seepage pressure automation system at Lianhua Power Plant is both necessary and timely.

A total of 34 seepage observation points need to be constructed, including 2 for seepage, 8 for the second dam, 7 for the main dam, 1 between the two dams, 6 for the second dam road surface, and 12 downstream of the second dam. All observation data will be aggregated to the central control room dam monitoring system through wireless transmission, achieving functions such as real-time data reception, uploading, statistics, and analysis queries.

1) The system meets the requirements of the technical specifications for automated safety monitoring of dams, technical specifications for safety monitoring of concrete dams, and technical specifications for safety monitoring of earth-rock dams.

2) The system software utilizes big data technology to integrate multi-source data of dams to build a dam monitoring data management center platform, which is a digital platform that integrates the safety monitoring and early warning management and sharing of reservoir and dam hydrological data, meteorological environment, dam body, and equipment facilities.

3) The system comprehensively applies technologies such as 3D GIS geographic information system, GPS positioning system, RS remote sensing, mobile/broadband networks, Internet of Things, and multimedia, achieving a wide range of data interfaces for hydrology and meteorological data, greatly facilitating the efficient operation and safety management of dams and water conservancy authorities.

4) The monitoring management station can also access mobile apps through the mobile internet, enabling mobile monitoring and management services for dam monitoring, allowing managers to grasp the operational status of the dam and its facilities anytime and anywhere, assisting in management.

5) The monitoring terminal is designed with video and anti-theft functions, equipment status monitoring, and fault diagnosis functions, capable of real-time online monitoring of the normal working status and abnormal warnings of each device and dam through the central station, facilitating the safe and efficient management of the dam.

1) Working Conditions

Collection device: Temperature: -20 to 60℃, allowable relative humidity: ≤95%

Monitoring management station: Temperature: 0 to 50℃, allowable relative humidity: ≤85%

2) Surrounding Environment Requirements

No explosion hazard, no corrosive gases and conductive dust, no severe mold, no intense vibration impact sources.

The grounding resistance of the monitoring station should not exceed 10 ohms.

The grounding resistance of the monitoring management station and monitoring management center station should not exceed 4 ohms.

3) Power Supply Requirements

AC power supply: AC 220V, allowable deviation ±10%.

Uninterruptible Power Supply (UPS), when the AC power supply is cut off, the UPS should maintain normal operation for no less than 30 minutes.

4) Performance Indicators

The system measurement accuracy should meet the requirements of DL/T5178, SL60, and SL268.

Measurement cycle: greater than 10 minutes, adjustable according to needs and characteristics of the measuring device (with or without control components).

System sampling time:

Routine inspection: no control, normal state 1 quick measurement, less than 1 hour; with control, normal state measurement, less than 2 hours.

Selected measurement (single point): no control, normal state measurement, less than 1 minute; with control, normal state measurement, less than 10 minutes.

No control, quick measurement, less than 0.5 minutes.

Response time for calling a new screen (90% of the screen): ≤1s.

Dynamic data refresh time on the displayed screen: ≤1s.

Response time for main control level control function: ≤1s.

Time from alarm or accident occurrence to sound output on the screen: ≤1s.

Average fault-free working time (MTBF): 50,000 hours.

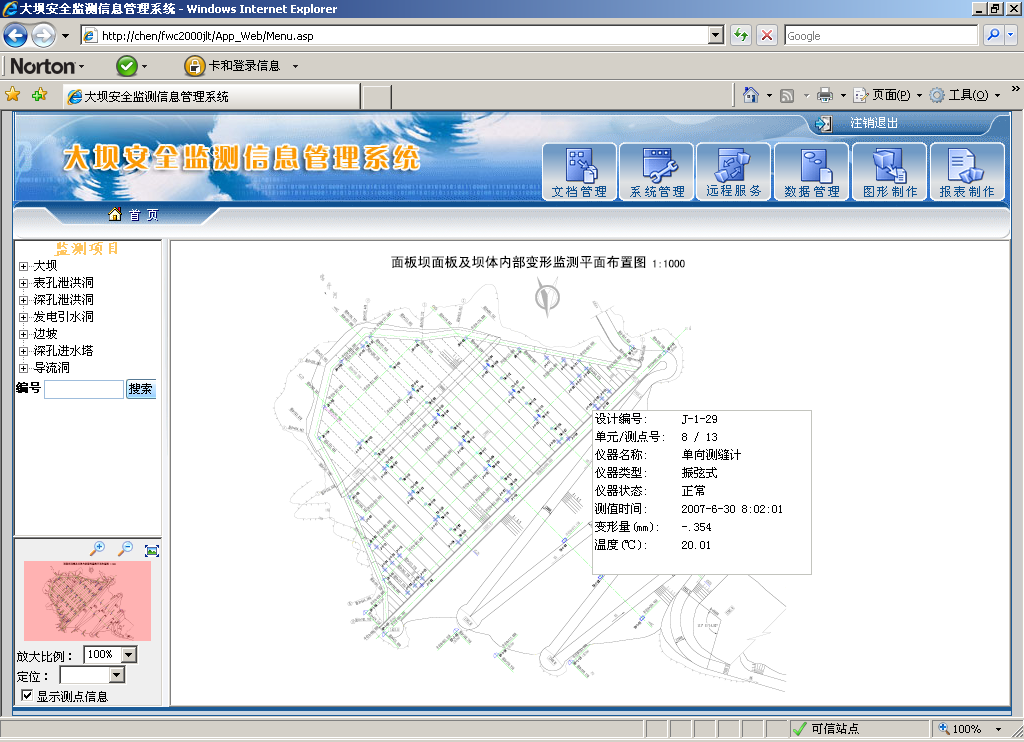

1) The system's巡测 (巡测) and选测 (选测) functions allow for data collection methods to be categorized into central control and automatic control. It enables real-time collection of operational parameters, equipment parameters, meteorological information, and status parameters at various measurement points of the dam, gathering data such as displacement, deformation, stress, cracks, saturation line, seepage flow, soil pressure, and pore water pressure for real-time data monitoring.

2) The system display function can display the overall layout of the building and monitoring system, the composition of each monitoring subsystem, process curves, alarm status display windows, etc.

3) The system operation function implements monitoring operations, input/output, display printing, reporting the current measurement value status, calling historical data, and evaluating system operation status on the computer at the monitoring management station or the computer at the monitoring management center station; it provides corresponding prompts based on program execution status or system working status; modifies system configuration, conducts system testing, and system maintenance, etc.

4) The system data communication function includes bidirectional data communication between the data acquisition device and the monitoring management station computer, as well as between the monitoring management station and the internal monitoring management center station and external network computers.

5) The system network security protection function ensures the secure operation of the network; it has multi-level user management functions, with multi-level user permissions and multi-level security Passwords, effectively managing the system's security.

6) The system has a self-checking function to facilitate timely maintenance.

7) The system has engineering safety monitoring management, online monitoring, offline analysis, database management, safety management, and other functions, including manual/automatic data collection, offline state analysis of measurement values, and graphical report production, which are basic contents of daily engineering safety management.

8) The system has a manual data input function, which allows for easy input of measurement points that have not implemented automated monitoring or data that has been manually supplemented due to system failures.

9) The system has an interface for communication with portable computers or reading instruments, using portable computers or reading instruments to collect monitoring data for manual supplementation, comparison, or to prevent data interruption.

The smart dam supervision system equipment will have different equipment configurations, installation requirements, and system integration application methods based on the project's construction or renovation scope, scale, technical requirements, and investment. The following is only a reference for the selection of equipment for the dam safety monitoring automation system.

Typical equipment configuration of the smart dam supervision system

The next one: