Intelligent Pump Station Supervision System

- Overview

- Main Features

- Main Indicators

- Main functions

- Device Configuration

The pump station automation control system is suitable for remote monitoring and management of booster pump stations in urban water supply systems. The management personnel of the booster pump station can remotely monitor the water level of the clear water tank or the inlet pressure, the working status of the booster pump group, the outlet flow, the outlet pressure, etc., at the pump station monitoring center of the water supply company; it supports manual control, automatic control, and remote control of the start and stop of the booster pump group; during fiber optic communication, panoramic and important workstation monitoring of the station can be achieved, realizing unattended operation of the pump station.

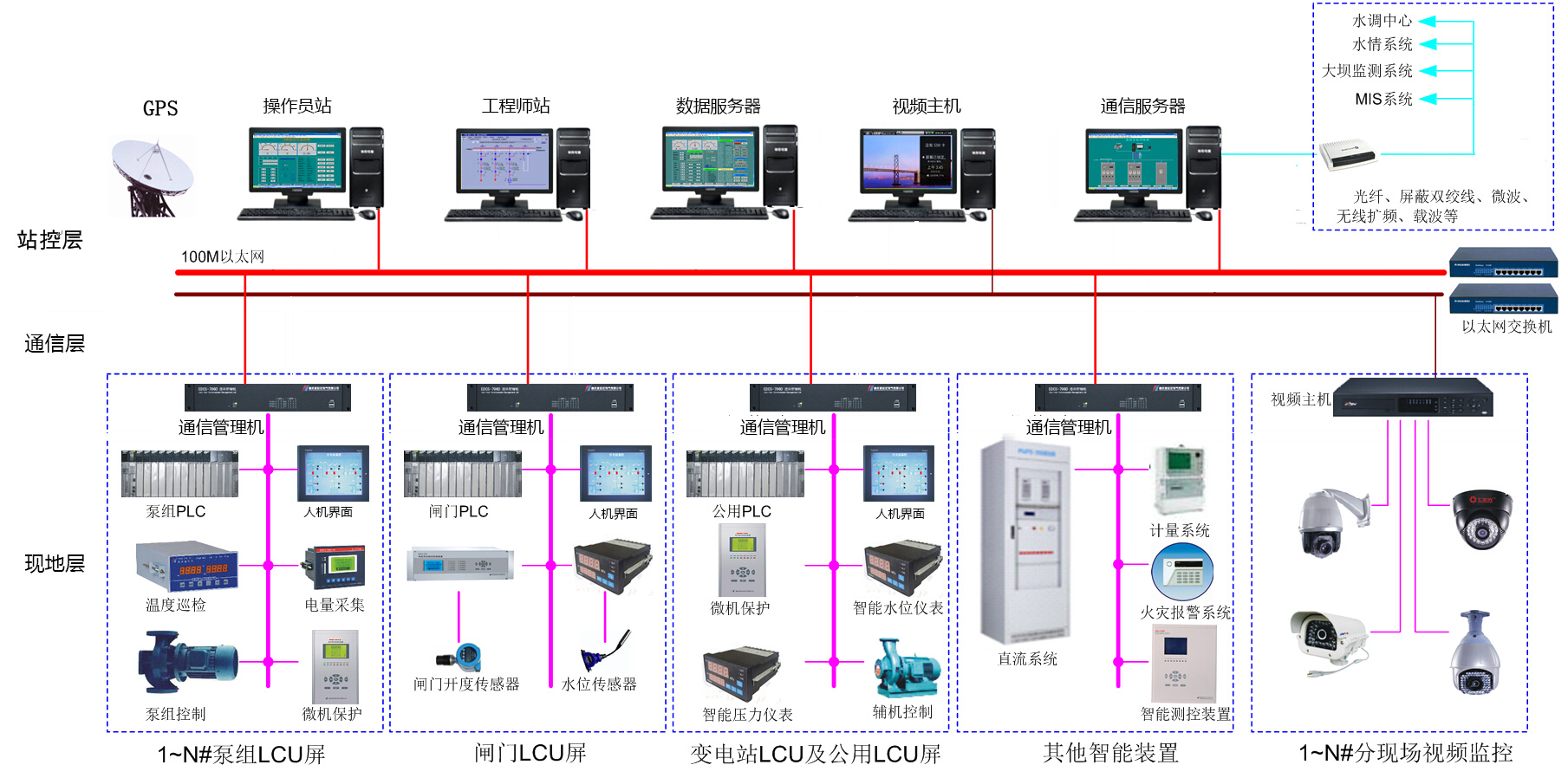

Figure 1: Typical network diagram of large and medium-sized intelligent pump station supervision system

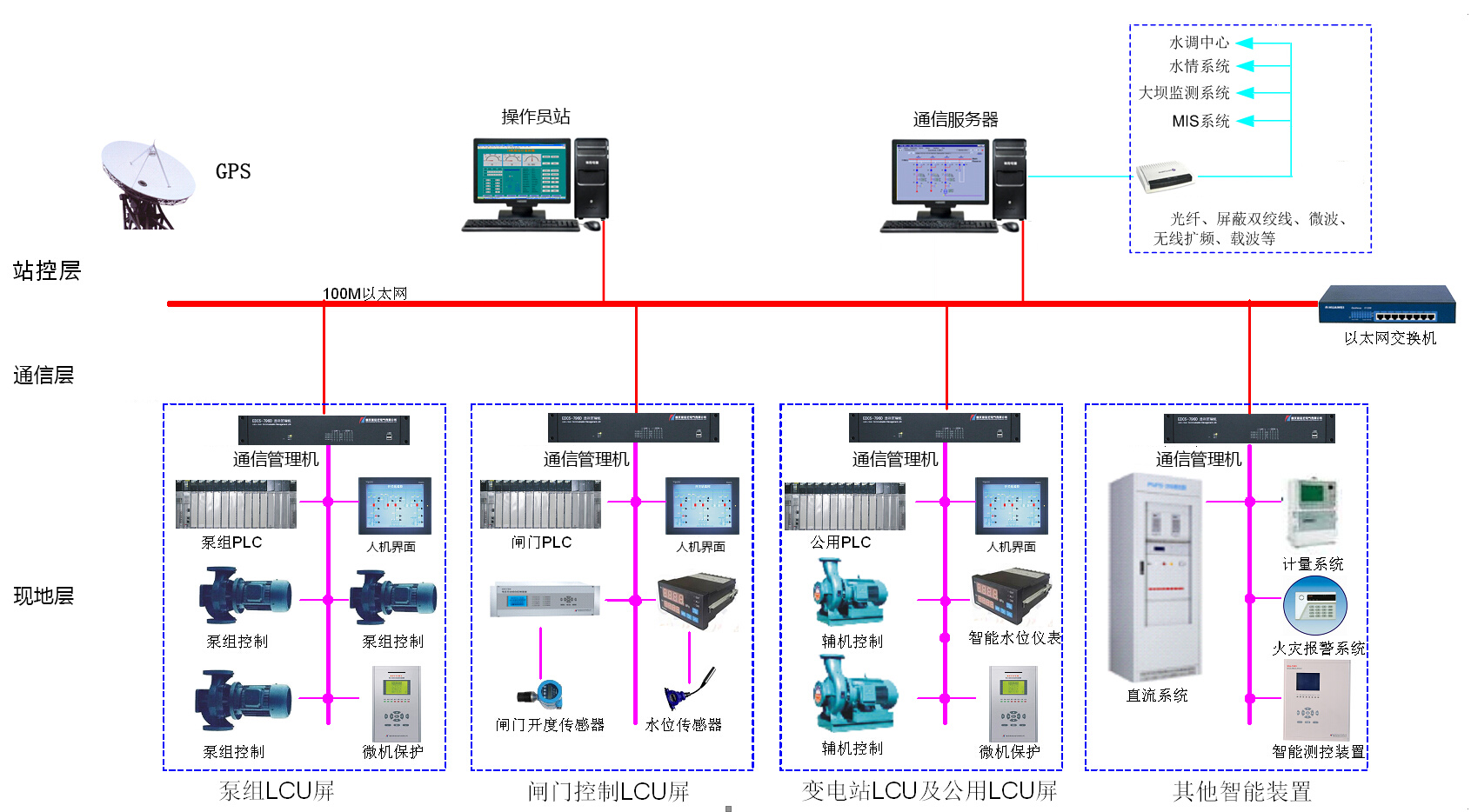

Figure 2: Typical network diagram of small and medium-sized intelligent pump station supervision system

Typical project: Intelligent transformation project of Kizil-Tepa-1 pump station in Uzbekistan

Project overview: The pump station is located in Kizil Tepa town, Navoi region, Uzbekistan, about 540 kilometers from the capital Tashkent. The total pumping capacity of the project is 42m³/s, and the pump station is equipped with 26 horizontal double-suction single-stage centrifugal pumps, with a single pump motor power of 2000kW and a single pump flow of 1.75 m³/s, and the pump station head is 80 m. Our company mainly provides self-control, fire protection, UPS, computer equipment and its spare parts for this project, including: installation and commissioning, training, and technical services for equipment such as technical water supply systems, drainage and dewatering systems, vacuum systems, fire protection systems, computer systems, uninterruptible power supplies, and DC systems, as well as public systems.

1) The monitoring center can display the water level of the pool, the electromagnetic valve of the pump station, the operating status of the pump, as well as voltage, current, sewage flow, pipeline pressure of the pump station, power supply status, etc. in real-time. It enables remote monitoring and management of the pump station, improving the management department's ability to respond to and handle various environmental issues of the pump station in a timely manner.

2) It has achieved a high degree of automation, allowing remote control of equipment through an automated control system, intelligently controlling the operation of the pump station, realizing unattended operation on-site, and saving a large amount of manpower and resources.

3) The pump station automation monitoring system has a complete early warning and alarm function, which can promptly alarm for current and voltage over-limit, water level over-limit, inflow or outflow pressure over-limit, and equipment failures. It also reports to the monitoring center, helping to identify problems and reminding users and staff to know the fault issues as soon as possible and carry out timely inspection and maintenance, thus improving the safety of equipment operation.

4) It has achieved centralized and unified management of data parameters and operating status of various pump station equipment, reducing the workload of maintenance personnel and lowering the management costs of the pump station.

5) The system has regular storage records of on-site data information, operational data information, historical fault issues, historical alarms, etc., providing great convenience for operators' future inquiries.

6) It has remote maintenance capabilities, allowing remote settings and modifications of terminal operating parameters, facilitating users in remotely maintaining terminal equipment.

1) Operating environment parameters

Ambient temperature: -20 to 50℃, allowable relative humidity: ≤90%

2) Current/voltage error: ≤±0.5%

3) Power/energy error: ≤±1.0%

4) Control and adjustment accuracy: 100%

5) Electrical quantity collection period: ≤1s

6) Non-electrical quantity collection period: ≤1s

7) Status and alarm point collection period: ≤100ms

8) SOE record resolution time: ≤2ms

9) Data transmission time of changes collected by LCU to real-time database: ≤1s

10) LCU response time to control command: ≤1s

11) Response time to call new screen: ≤1s

12) Dynamic data refresh time on displayed screen: ≤1s

13) Main control level control function response time: ≤1s

14) Time from alarm or incident occurrence to sound output on screen: ≤1s

15) System availability: ≥99.9%

16) Mean time between failures (MTBF): 50000h

1) Real-time Data Collection

The system can collect real-time data such as import and export flow, water level, temperature, oil pressure, pump inlet and outlet water pressure, cooling water flow, blade angle, as well as circuit breaker position, pump operating conditions, blade position, travel switch position signals, and speed relay signals.

2) Real-time Data Processing

The system has various functions such as limit monitoring and alarm processing for data, remote signal monitoring and processing, and operational data calculation and statistics.

3) Relay Protection

Based on the national grid's "six unifications" and the Southern Power Grid relay protection design specifications, it implements protection for pump station lines, main transformers, capacitors, motor units, and other equipment in the power system.

4) Operation and Automation Control

Mainly includes control of circuit breakers and knife switches, start and stop control of pump units, emergency shutdown operations for pump units, adjustment of pump blade angles, start and stop control of public equipment, start and stop control of gates, capacitor switching operations, transformer tap adjustment, remote retrieval of protection settings, remote modification of settings, and control of pressure plates.

5) Accident Alarm

Provides real-time alarm and historical query printing functions for events. Alarm types include warnings, actions, operations, systems, telemetry limit exceedances, and remote signal displacements. Historical event queries can be categorized by time period, plant information, group information, type queries, or combinations of various methods.

6) Report Curves

Provides the function to query and print historical data in the form of reports and curves. Reports include daily, monthly, and annual reports, each edited flexibly and conveniently by report editors; historical data for any telemetry point can be reviewed in curve form.

7) Module Management

Mainly used to manage protectors, PLCs, and other intelligent communication modules. Functions include viewing the type and name of each module; viewing, modifying, and printing the settings of each module; viewing telemetry and remote signal data of each module; issuing commands for time synchronization, reset, etc.

8) Data Communication

The configuration of communication modules is related to on-site requirements, generally including protector communication modules, PLC communication modules, dispatch communication modules, reserved communication modules for other systems (such as water condition monitoring systems, fire alarm systems, etc.), and other intelligent communication modules (such as temperature inspection instruments, electric meters, excitation, speed regulator modules, etc.). Real-time communication status and data can be viewed through the message viewing window.

9) System Time Synchronization

The system has clock synchronization capabilities, allowing the system clock to synchronize with satellite clocks.

10) Human-Machine Interface

Mainly includes electrical main wiring diagrams, single machine monitoring screens, measurement summary screens, system operating status diagrams, geographical wiring diagrams, motor control diagrams, start-stop flow charts, real-time status of pump units, gates, auxiliary machine operating conditions, and signal quantities, providing manual settings and operation interfaces, visually displaying historical information and comparative information of flow rates and water levels in curves, bar charts, and controls.

11) Permission Management

Provides functions for editing and verifying operation passwords. All permission checks and verifications in this system are implemented through the permission management module.

12) Online Monitoring and Fault Diagnosis of Main Equipment

Configurable online monitoring and fault diagnosis system for equipment, achieving online monitoring and fault diagnosis functions for major equipment in the pump station, which can improve equipment operational integrity, reduce downtime, and lower maintenance costs. Online monitoring equipment in the pump station includes switch cabinets, transformers, capacitors, motors, pump units, and gate valves.

13) System Self-Diagnosis and Self-Recovery

The system can perform self-diagnosis of hardware and software at regular intervals during online or offline operation, display the location of faulty modules, and print recorded test results. When a fault is diagnosed, it can automatically lock the faulty unit and issue an alarm signal. The system has self-protection functions in case of power failure, interference, or freezing, and can automatically switch to normal working status.

14) Operational Guidance

The computer monitoring system can conduct functional development and provide operational guidance for operating personnel through the engineer operator station or remote communication server. Software locking ensures that these operations do not affect the normal operation of the online host.

15) WEB Publishing

Using Internet browsers to achieve web browsing of the pump station monitoring and production management system. Supports remote real-time screen browsing, real-time data queries, remote report displays, historical curve queries, historical events, and production information queries.

16) Mobile Management

The system supports data information publishing, human-machine interaction, and process operations through mobile terminals, achieving mobile office for the automation operation, maintenance, and management of the pump station.

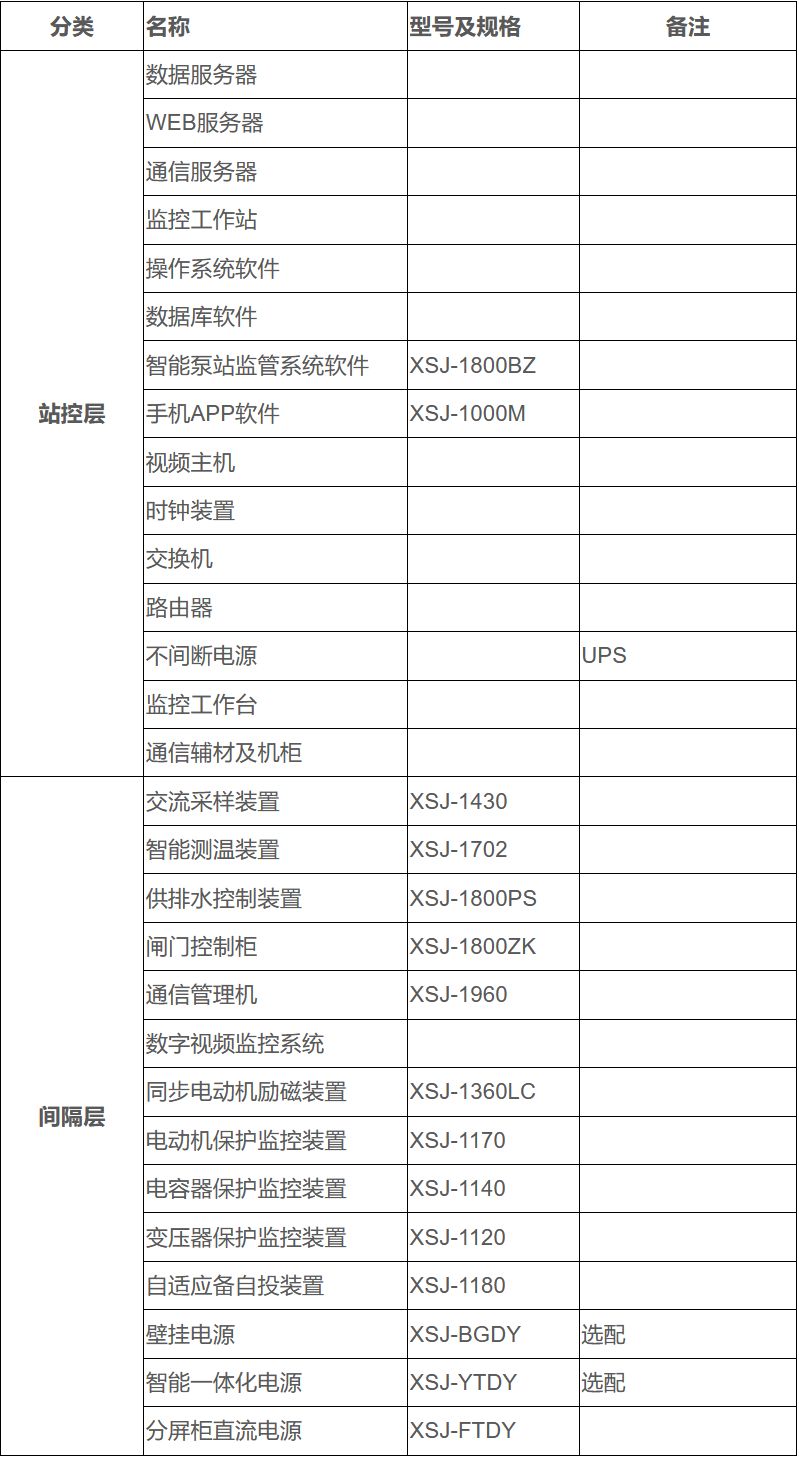

The intelligent pump station monitoring system equipment will have different equipment configurations, installation requirements, and system integration application methods based on the project's construction or renovation scope, scale, technical requirements, and investment. The following is only a reference for the selection of pump station system equipment.

Typical equipment configuration of the intelligent pump station monitoring system

The next one: